Structural corrosion modeling has long been considered a tough problem to solve. The combination of coupled physics effects and metal shape change pose quite a computational challenge. Fortunately, engineers have found that multiphysics software brings a solution. A great example of this is coming up at the COMSOL Conference 2013 Boston this fall, when Dr. Siddiq Qidwai from the Naval Research Laboratory will take the stage and let us in on how to properly model structural corrosion.

The U.S. Navy’s Premier Research Laboratory

This past July, the Naval Research Laboratory (NRL) celebrated 90 years. When it was created back in 1923, NRL was the Navy’s first research operation. Early achievements include gamma-ray radiography for inspecting naval ship metal castings and welds, and, perhaps the most well-known invention, the first U.S radar equipment. In the 1960s, they unveiled a novel time-based navigational system, which led to the global positioning system (GPS). Then, in 1985, an NRL scientist won the Nobel Prize for research on molecular structure analysis. The list goes on, and today it is one of the Navy’s premier research organizations, and it keeps on innovating. This great research laboratory’s work covers just about every field within military science and technology, such as maritime applications and ocean, atmospheric, and space sciences.

Accurate Corrosion Modeling using Multiphysics Software

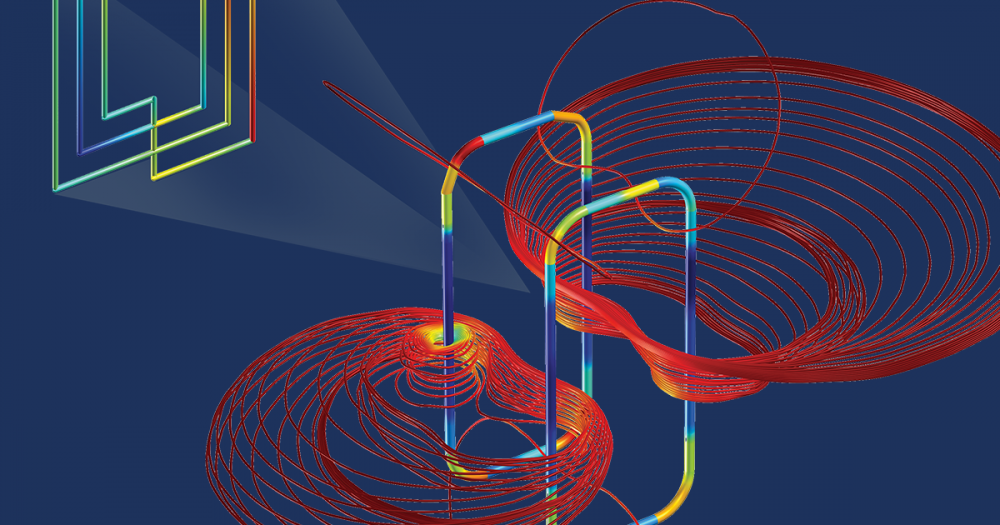

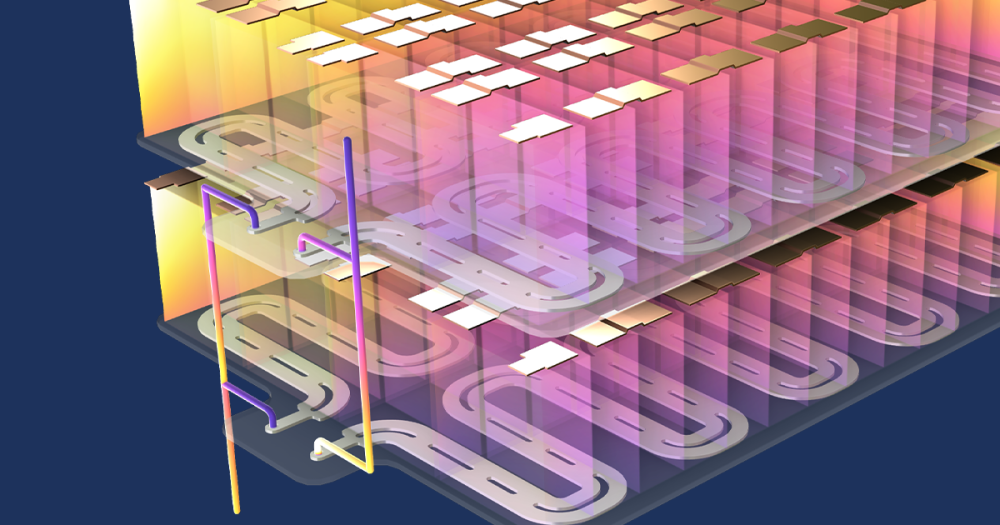

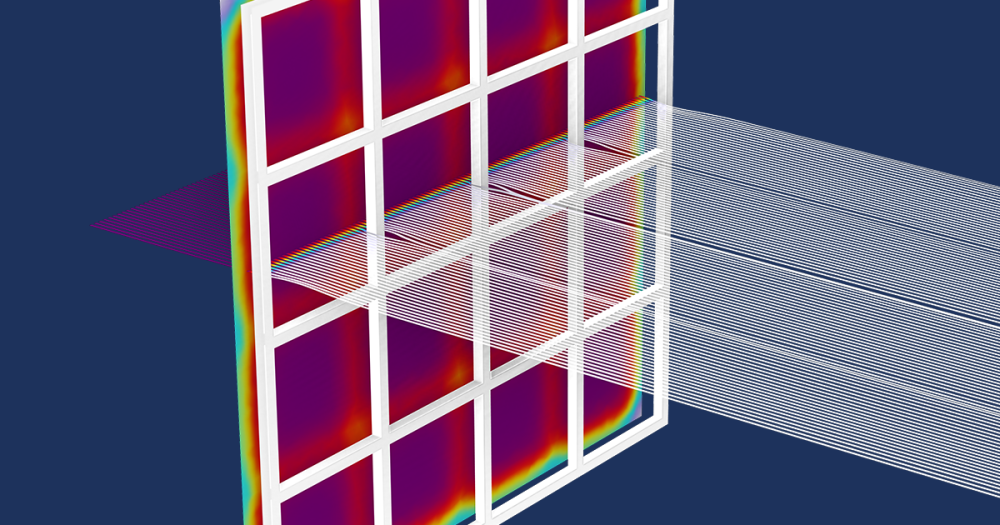

One of the areas where NRL is currently pursuing research in is corrosion. Structural corrosion is a major challenge for naval and maritime industries, and the cost of preventing corrosion from affecting the performance of equipment, systems, and vessels is enormous. Hence, the investment in accurate computational modeling is of great importance for thoroughly understanding and mitigating the effects of corrosion. Expertise in the simulation of corrosion can be found at the Multifunctional Materials Branch of the US Naval Research Laboratory in Washington, DC. There, Dr. Siddiq Qidwai conducts research on microstructure-sensitive corrosion modeling. This particular problem is challenging to simulate accurately, as it includes several coupled physical effects. The following phenomena need to be included in a realistic simulation:

- Electrochemical reactions

- Mass balance of multiple species

- Constitutive relations of electrolyte

- Moving metal-electrolyte interface

This is a great example of where COMSOL Multiphysics makes a difference, and in his keynote titled “The Story of Microstructure-Sensitive Corrosion Pit Growth and Mechanical Performance”, Siddiq will take us through the continually evolving journey of this exciting modeling project.

The structural corrosion modeling keynote will be held on October 10th, day two of the COMSOL Conference 2013 Boston.

About the Keynote Speaker

Dr. Siddiq Qidwai is a Mechanical Engineer at the Multifunctional Materials Branch of the US Naval Research Laboratory (NRL). He specializes in computational mechanics and materials science, and focuses mainly on constitutive modeling and multiphysics phenomena. Dr. Qidwai is currently researching microstructure-sensitive corrosion modeling, biomechanical modeling of the human head under extreme conditions, and electrically-assisted deformation of metals. He has published eighty-five papers, including twenty-three archival journal papers and two book chapters, and holds one patent. He has co-authored a paper that was selected for NRL’s 2010 Alan Berman Research Publication Award. He received his master’s degree and doctoral degree in aerospace engineering from Texas A&M University, and his bachelor’s degree in mechanical engineering from Middle East Technical University (Ankara, Turkey).

Dr. Siddiq Qidwai,

Mechanical Engineer,

Multifunctional Materials Branch,

US Naval Research Laboratory (NRL).

Comments (0)