Over the years, the size and cost of 3D printers have decreased, offering new uses for this growing technology. In response to this development, more and more teachers have begun to utilize these devices within their classrooms, helping students learn in a hands-on way.

3D Printing: From Design and Manufacturing to the Classroom

The creation of the first 3D printer in 1984 brought about a new method of manufacturing for a number of industries. Automotive and aviation industries, among others, implemented this technology into their manufacturing process, developing prototypes from digital data. In addition to reducing costs and the amount of material used, 3D printing also allowed for greater customization and eased the process of making changes to the design.

The first types of printers to emerge, however, were both large and expensive. Thus, they were typically used in commercial industries to develop more valuable parts in a lower volume production.

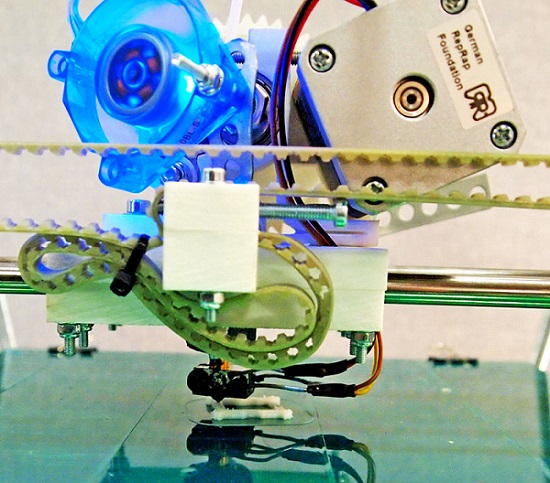

Now, envision this technology at your fingertips, limited only by your ideas on what to create. With a decreased cost and greater portability, 3D printers are now popping up in homes, offices, and — you guessed it — classrooms. While the technology is still being developed, many educational settings have introduced 3D printing to their students in the hopes of helping them explore their creativity through design and printing.

3D printers have become a more portable technology. (“3D printer” by Tiia Monto — Own work. Licensed under Creative Commons Attribution-Share Alike 3.0 via Wikimedia Commons).

A Resource for Student Engagement

With the range of prototypes that can be designed on a 3D printer, this technology has been used as a resource in a number of course types. At the University of South Florida, 3D printing is used to recreate exact replicas of ancient artifacts to share with students. With the help of laser scanning techniques, researchers can reconstruct artifacts based on scanned data and information from their studies. Students are then able to touch and see these artifacts from around the world within the comfort of their own classroom, all without the risk of causing damage to the original piece.

Meanwhile, an engineering class at University of Virginia took the technology into their own hands, precisely replicating a Rolls-Royce jet engine using plastic engine parts. Using refined CAD files, the students organized and assembled the printed pieces to replicate the engine. Along with learning the ins and outs of the engine’s design, the class was also able to further explore the manufacturing process as well as potential constraints.

At Northeastern University, students, faculty, and staff have access to 3D printers much like the traditional printers they’ve accessed for years. The university’s 3D printing studio features a variety of additive manufacturing technologies, including 3D scanning, laser cutting, powder printing, fused deposition modeling, and stereolithography. In addition to these 3D modeling and fabrication technologies, the university also offers consultation services so that individuals can get acquainted with the equipment and receive guidance in beginning their design project.

COMSOL Summer Interns 3D Print

Prompted by their own curiosity and interest in the technology, a couple of summer interns here at COMSOL had the chance to try out our own 3D printer back in 2013. With the help of my colleague Dan Smith, they searched for files in an online 3D printing library and printed out an assortment of trinkets, including hockey logos, dice, and seahorses. This experience was noted as one of the highlights of their internship — a perfect combination of fun and learning.

Comments (0)