You may be familiar with the humming start of the mechanical fan that turns on when booting up your laptop computer. Such a fan is necessary to prevent electronic devices from overheating, and the accompanying whirring sound of the cooling system is an unavoidable side effect. As electronic devices become smaller, this mechanical fan must decrease in size as well, and therefore spin faster and faster in order to deliver the same amount of heat dissipation as a larger fan. Not only are these smaller blades loud, but industry advancements and consumer expectations now call for the production of devices that are simply too thin to contain an effective fan. In order to address these issues, there are many research projects devoted to discovering new heat dissipation techniques that not only meet the space constraints demanded by developing technologies, but are also quiet.

Heat Dissipation Using a Corona Discharge

Heat dissipation, an essential requirement in electronic devices, is typically accomplished via a small mechanical fan. For decades, the airflow created by this mechanical fan has been the only means of cooling electronic components, and engineers have all but exhausted the potential for delivering smaller, more compact, and quiet fans. Because of this, engineers from a variety of industries have been looking for more effective electronics cooling methods, and there have been quite a few new inventions that have recently been developed. One of the most promising of these new cooling techniques uses corona discharge to create a cooling stream of air. The technique, known as electric wind or ionic wind, includes two electrodes that are used to generate airflow without requiring (noisy) moving mechanical parts.

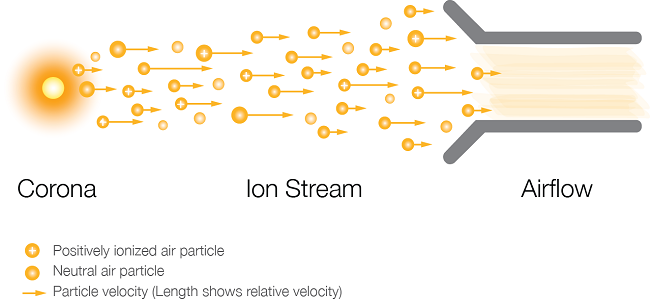

In these silent cooling devices, airflow is created when one of the electrodes in the system, known as the corona electrode, produces positively charged gaseous ions, while the other electrode, the collector or counter electrode, attracts them, creating a current of positively charged nitrogen ions between the two electrodes. When these moving ions collide with ambient air molecules, momentum is transferred between the two particles, and a continuous stream of air is produced, which then propagates to other molecules in the system through a cascading effect. Next, these electrons and air molecules travel through an airflow duct, where they are directed toward electronic systems in the device. Once the ions reach the collector electrode at the end of the duct, they are de-ionized.

The working principle behind a corona discharge design, where ions generated by a corona electrode are traveling towards an air duct. Image courtesy of Tessera Technologies Inc.

When the device is on, a voltage is applied to one of the electrodes, generating a strong electric field around it. This electric field then ionizes nitrogen molecules in the air, creating positively charged ions. A corona discharge occurs when the electrical field created around the corona electrode is strong enough to create a conductive region or plasma region surrounding the electrode, but is not strong enough to cause arcing or electrical breakdown to objects nearby. The ionized nitrogen molecules then drift from the plasma region surrounding the corona electrode toward the counter electrode, often passing through an air duct as shown above.

A Multiphysics Approach to Silent Electronics Cooling

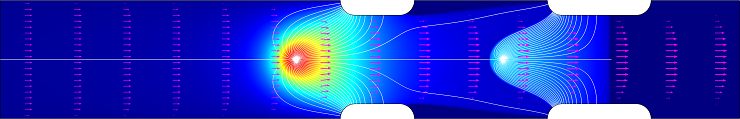

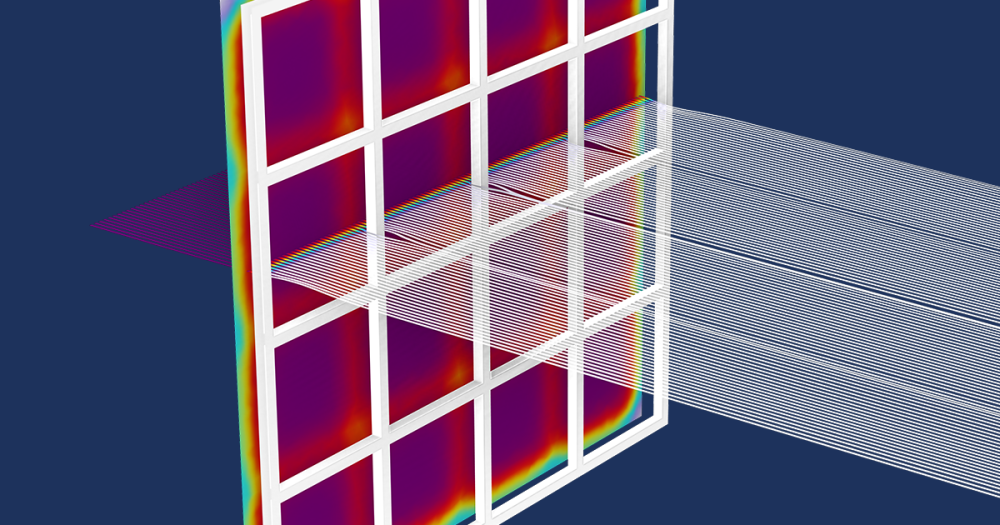

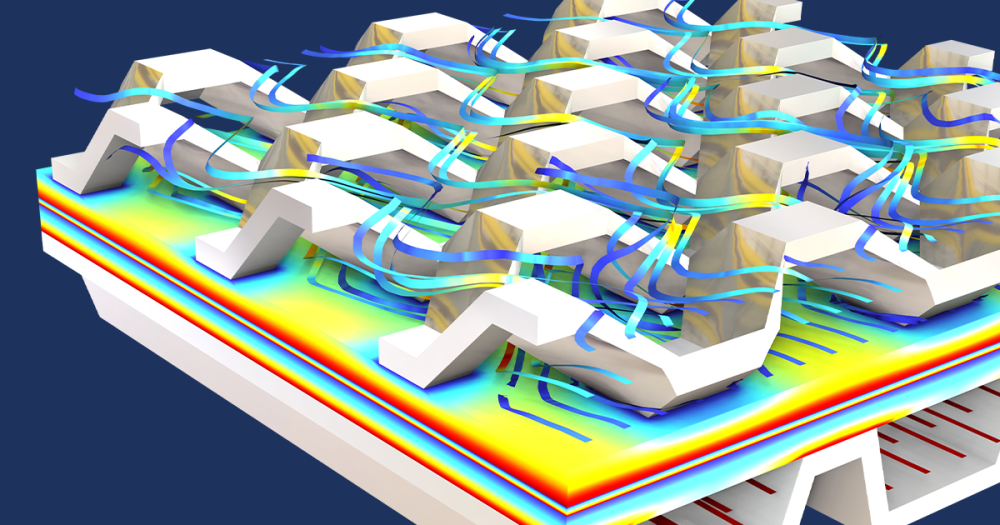

One of the front-runners in the design of silent electronics cooling devices is Tessera Technologies Inc., who has patented what it calls the Tessera Silent Air Cooling™ system. The system, which was first developed by Nels Jewell-Larsen, a University of Washington student, uses electric wind and corona discharge to create a cooling system for laptop computers. The system was designed and simulated with COMSOL Multiphysics, allowing the research and development (R&D) team at Tessera to understand the minute inner workings of the device. Their final simulation took into account many different physics effects, including electrostatics, charge generation and transport, fluid dynamics, and heat transfer. A plot of the multiphysics simulation developed by the team is shown below:

Multiphysics simulation of the Silent Air Cooling™ air mover. The surface map shows the space charge density (where the red color indicates higher density), and the white lines denote space charge flux line. White arrows display the air velocity, with the arrow length linearly scaled to velocity.

“Because the electric field does not change with time, there are no pressure waves, so there is virtually no sound,” explained Larsen in a recent article in COMSOL News 2013. The resulting Silent Air Cooling™ system is not only completely silent to the human ear at 15 dBA, but it can also fit into a 4 mm thick space, and Tessera has been able to demonstrate that the system works in Ultrabook™ devices.

In Other Electronics Cooling News…

Ionic Wind Generator Keeps Things Cool at Apple

According to AppleInsider, Apple® Inc. has been working on a device similar to Tessera’s, called the “Ionic Wind Generator”. It was patented late in 2012, and the patent describes a system that uses corona discharge to create an electric wind for cooling electronic devices. The patent also details an additional technique that allows the airflow to be redirected inside the system using magnets or electromagnets. As of now, Apple has yet to implement this cooling system in a consumer device, but the patent notes that it may be possible to use the invention not only in desktop and laptop computers, but also in cell phones, media players, and tablets.

A Jet Engine Cooling Approach Redesigned for Electronics

While reading about corona discharge and its use in silent electronics cooling, I came across another approach that solves both the space and noise constraints of the electronics industry in a completely different way. The device, known as the Dual Piezoelectric Cooling Jets (DCJ), was developed by General Electric® (GE) for use in jet engines. The approach now shows potential for silent cooling in laptops and other electronic devices. The working principle behind the DCJ device is quite simple; it uses the same technique as a diaphragm or pair of lungs that contract and expand to pull and push air, creating a cooling stream of air.

In a press release from December of 2012, GE described the device as “behave[ing] as a microfluidic bellows that provide high-velocity jets of air to cool electronic components. The turbulent air flow of the DCJ increases the heat transfer rate to more than ten times that of natural convection… such that the DCJ can now be considered as an optimal cooling solution for ultra-thin consumer electronics products.” The system has yet to be implemented and sold in a consumer device, but the technique does show promise for use in laptops, and GE claims that the energy efficient system may be able to add up to 30 minutes to a computer’s battery life.

Additional Resources

Each of these new designs show promise for the future of electronic devices, preventing electronics cooling from becoming a limiting factor in the improvements and innovations made in the electronics industry. Learn more about these new techniques from the resources below:

- Learn more about Tessera in the article “Silent Air Cooling: A New Approach to Thermal Management” on page 26 of COMSOL News 2013

- Read about Apple’s “Ionic Wind Generator” in an article by AppleInsider

- Watch a video describing GE’s Dual Piezoelectric Cooling Jets

Comments (0)