Degassing of PP Pellets in a Silo: Keeping C9 Concentrations Below the Lower Explosion Limit

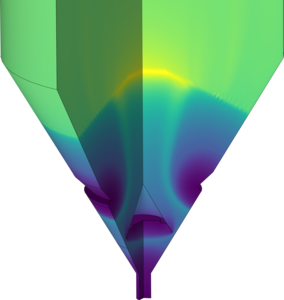

When polypropylene (PP) is produced it contains impurities in the form of dissolved gasses. These gasses can be removed by heating the material (in the form of pellets in a silo) and flushing with plenty of fresh air. However, one of the gasses is C9, which is flammable. We built a model to find the minimum flow rates to make sure that the C9 concentration at any point in the silo is always well below the lower explosion limit (LEL).

The process goes as follows: a silo is filled with polypropylene pellets at a certain temperature T=Tpellets, in. The geometry of the porous bed thus changes over time. During this process hot air (T=Tair) is pumped into various inlets in the silo, heating the pellets. Because of the elevated temperature the degassing goes faster. The bottom part of the pellet bed is hot and the top part (fresh pellets) is ‘cold’ (T=Tpellets, in). The front between these parts moves upwards until the whole silo is hot. The hot pellets are releasing C9 into the air flow, whereby the degassing rate decreases as the pellets are depleted of C9.

The implementation in COMSOL Multiphysics® contains the following ingredients: • Because the diameter of the silo is changing along the height of the silo, an ODE is defined that computes the filling level consistent with the constant mass flow of PP pellets. Using this filling level various porous bed properties such as heat capacity and permeability are defined as function of time. • The porous media flow is described by the Ergun equation, which is solved for with one of the equation based PDE interfaces. • A two-temperature ‘local thermal non-equilibrium’ model (from the Heat Transfer Module) is used to model the heat transfer between the bed and the air. There are two temperatures that are solved for: the pellet bed temperature (heat transfer in solids) and the air temperature (heat transfer in fluids). • For the degassing rate and depletion of C9 from the pellets, a domain ODE is added that basically tracks the temperature history of the pellets at a certain location, based on which the current degassing rate can be determined. • A Transport of Diluted Species interface solves for the C9 concentration including advection and diffusion and a source term based on the degassing rate.

The spatial and temporal maxima of the C9 concentration are extracted to make sure that they are below the LEL. Various parameters (e.g. inlet flow rates and air temperature) can be varied to make sure that there is a comfortable safety margin.

Téléchargement

- Wesselink_6221_presentation.pdf - 2.7MB

- Wesselink_6221_poster.pdf - 2.83MB