Geometric exploration and optimisation of porous ceramic reactors for bioethanol production

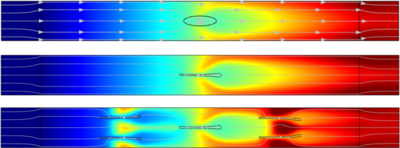

This work investigates the design of porous ceramic reactors for continuous bioethanol production through simulations using COMSOL Multiphysics®. Porous ceramic structures will be seeded with the yeast Saccharomyces cerevisiae and exposed to a continuous flow of glucose solution, from which ethanol will be produced. Using parametric studies, the effect of the porous microstructure and macrostructure on flow rate, pressure drop, and ethanol production will be explored through microscale homogenisation and macroscale modelling. Subsequently, geometric optimisation will be performed on the micro- and macrostructures in order to maximise bioethanol production, while keeping a moderate flow resistance.

Two levels of models for the chemical reaction will be explored: a simple model based on non-reversable reaction of two species, where the yeast culture is kept constant; and a more complex model where the growth of yeast is also considered. The latter model builds on an old COMSOL Multiphysics® model from the Application Library considering beer fermentation. Furthermore, the work combines three COMSOL Multiphysics® modules: CFD Module, Chemical Reaction Engineering Module, and Optimization Module.

The results are expected to pave the way towards more efficient continuous bioethanol production through simulation and geometric optimisation, but are likely to be broadly applicable to the design of other porous ceramic bioreactors as well.

Téléchargement

- COMSOL_presentation.pptx - 1.46MB