Modeling and Experimental Evaluation of Structured Powder Dissolution

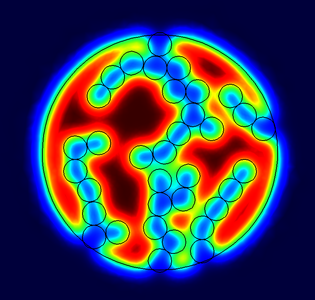

The dissolution behaviour of powders is an important factor when evaluating their applicability for customer and industrial use. The dissolution speed of a powder can be influenced by a number of parameters. Important parameters are particle size, porosity and powder composition amongst others. The dissolution process was simulated using COMSOL Multiphysics®. Model geometries of particles set up of varying fractions of soluble and insoluble material with different porosities and particle sizes were generated using LiveLink™ for MATLAB®. Dissolution modeling was based on the Fick’ian law of diffusion and the Chemical Reaction Engineering Module, specifically the Transport of Dilute Species interface, was used to implement the differential equation in the model. To evaluate the impact of particle size, porosity and proportion of soluble and insoluble material, parametric studies were run. Furthermore, the effect of a concentration dependent diffusion coefficient on dissolution was studied. In addition, model systems were created containing two different types of soluble material, of which one was dissolving at a higher speed than the other. The results of the COMSOL Multiphysics® simulation were compared to results obtained by implementation of the Finite Difference Method in MATLAB®. To evaluate the simulation, experimentally obtained dissolution data in form of turbidity measurements were used.

Téléchargement

- ruprecht_poster.pdf - 0.84MB

- ruprecht_abstract.pdf - 0.08MB