Modeling and Simulation Study of a Fixed-Bed Catalytic Reactor for the Hydrogenation of CO2 to CH4

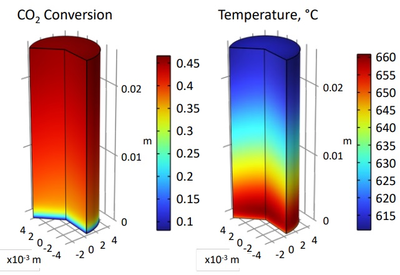

The "Power to Gas" technology is a promising alternative for storing renewable electrical energy through energy carriers. This technology involves using surplus energy from renewable sources to obtain green hydrogen through water electrolysis. Since hydrogen storage and transportation remain costly technological challenges, the obtained H2 can be reacted with captured CO2 to produce methane, resulting in Synthetic Natural Gas (SNG). Natural gas already has a well-established distribution network that would allow for the distribution of SNG. The methanation reaction also implies an engineering challenge. As a highly exothermic and reversible reaction, thermodynamics are unfavorable at high temperatures. Therefore, the use of an active and selective catalyst at low temperatures and a well-designed reactor that ensures efficient heat management are essential. The reaction undergoes a significant temperature rise due to the heat generated, resulting in a rapid escalation of the reaction rate. This phenomenon leads to a sudden and substantial increase in both conversion and temperature along the longitudinal axis of the reactor. However, the reaction comes to an abrupt halt when it reaches equilibrium, stopping any further advancement. The use of models to simulate the reactor behavior is a very valuable tool for proper reactor design. In this work, the commercial software COMSOL Multiphysics® was employed to create several models of methanation reactors. Using the Chemical Reaction Engineering Module and its associated interfaces, a fixed-bed reactor with a 10% Ni/alumina catalyst was simulated. The reactor is placed in a furnace and fed with CO2 and H2 in stoichiometric proportions. First, three zero-dimensional models were created: an isothermal model, an adiabatic model, and a model considering heat exchange with the furnace. The Reaction Engineering module, assuming an ideal plug flow reactor, was used. An optimization study was conducted to find the inlet gas temperature that maximizes CO2 conversion at the reactor outlet for each reactor configuration. One-dimensional (1D) models were implemented to simulate pseudo-homogeneous gas-phase reactive flow reactors and gas-phase flow through a porous medium. These models consider the transport of matter and energy in the axial direction of the reactor using the Concentrated Species Transport, Concentrated Species Transport in Porous Media, Heat Transfer in Fluids, and Heat Transfer in Porous Media interfaces. It was observed that the transport of matter and energy significantly changes the conversion and temperature profiles along the axial length of the reactor, particularly in the presence of a porous medium. Finally, two-dimensional (2D) models were implemented, considering the transport of matter and energy in the radial direction of the reactor. The Free and Porous Media Flow and Brinkman Equations interfaces were applied to describe the fluid flow in more detail. Significant velocity profiles were observed in the radial axis, which also influences the conversion profiles. The temperature profile is pictured in the figure where a hot spot can be seen. For a better understanding of the modules used during the development of the research the “packed bed reactor 3D” and the “steam reformer” models from the Application Library were employed as starting points.

Téléchargement

- paper_comsol_munich.pdf - 0.52MB

- Lacarra_6571_poster.pdf - 0.45MB