Time-Dependent Thermal Stress and Distortion Analysis During Additive Layer Manufacturing, by Powder Consolidation by Laser Heating

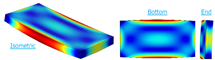

A time-dependent COMSOL Multiphysics model of an additive manufacture process, which uses powder consolidation by laser heating was developed, providing a platform to better understanding the manufacture process & provide a tool to reduce resulting distortion & optimization of an additive manufacture process. The model simulates a high intense laser energy source moving along a pre-defined time dependent path and is used to simultaneously fuse titanium alloy beads being laid down along the path of the laser on to a substrate component. The problem encountered with the current process is the development of residual stresses forming in the substrate component during additive layering and cooling; triggering undesired permanent deformations in the structure. It is believed that by adjusting the power, light intensity, focal diameter and the speed of the laser along its path, the resulting residual deformation can be minimized or eliminated, reducing quality control problems and ensuring compliance to the specifications of the final composite component. The model is used to predict the resulting residual distortion after cooling, due to the coupled thermal-stress as the titanium beads are laid along a path and fused simultaneously with a high energy laser onto a substrate component.

Téléchargement

- yeoman_poster.pdf - 2.28MB

- yeoman_abstract.pdf - 0.2MB