Consultez les proceedings de la Conference COMSOL 2020

Simulação Fluidodinâmica de um Digestor Contínuo para Produção de Celulose.

A obtenção de polpa celulósica antecede a produção de papel e envolve a separação das fibras da madeira mediante a utilização de energia mecânica, térmica, química ou a combinação desses processos. Esta operação é realizada em um reator, tubular, cilíndrico e vertical (tipicamente 6 m de ... En savoir plus

Chemical Reactions at Interfaces During Droplet Formation in Microchannels

Emulsions, small liquid droplets of oil in water or water in oil, find wide application in, pharmaceutical products, fine chemicals, analytical chemistry. Microfluidic devices allow creation of uniform droplets with a tight distribution. The COMSOL Multiphysics® software model presented ... En savoir plus

Lennard-Jones Potential Determination via the Time-Dependent Schrödinger Equation

The accurate atomic potential determination is an essential task in the molecular simulations, e.g. Grand Canonical Monte Carlo (GCMC). The ab initio simulations using the quantum mechanics would of great interest in the computational physical chemistry. The numerical simulation of the ... En savoir plus

Hybrid Resistive-Capacitive and Ion Drift Model for Solid Gas Dielectrics

INTRODUCTION: Many electrical insulation systems use a combination of gas and solid media. Typical examples considered here include the combination of solid epoxy insulation and SF6 in a gas insulated subsystem (GIS). To understand how such a system performs under DC voltages, accurate ... En savoir plus

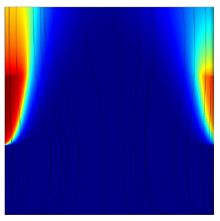

Study of Electrochemically Generated Two-Phase Flows

The dependency of electrochemical processes performances on mass transfer is well-known. Electrolyte flow in the vicinity of electrodes surface can enhance reactions due to increased mass transfer. This flow can be generated by the production of a gaseous phase, leading to a natural ... En savoir plus

Hydrodynamics and Mass Transfer in Taylor Flow

In the present work, numerical simulations of a Monolith Reactor (MR) are carried out in order to develop a pre-design tool for industrial-scale reactors applied to highly exothermal reactions. The reacting circular channels (2-4 mm internal diameter) are coated with a few micron thick ... En savoir plus

Na-MCl2 Cell Multiphysics Modeling: Status and Challenges

Introduction: After more than 20 years of experience in EV applications, the sodium nickel chloride technology is fully mature for large scale energy storage. Early on, mathematical modeling of Na-MCl2 cell (M standing for Fe or Ni) has attracted attention to help identifying predominant ... En savoir plus

Modeling and Simulation of Hydration Operation of Date Palm Fruits Using COMSOL Multiphysics

The control of the hydration during the thermal process of dates is crucial in order to save energy and to obtain a good quality for the final product. In this work, a theoretical model was developed in COMSOL Multiphysics software to describe the mass transfer phenomena involved in this ... En savoir plus

Virtual Modeling of Thermo-Physiological Comfort in Clothing

This publication aims to investigate conjugate heat and mass transfer around a clothed virtual manikin. This research can be performed at different scales: (1) at material scale where a piece of textile is investigated in 1D or 2D space or (2) at system level where a clothed cylindrical ... En savoir plus

Dried Reagent Resuspension for Point of Care Testing (Analysis at the Patient Bedside)

A microfluidic component was designed to collect blood from a finger prick by capillary flow and to perform biological analysis. It was used to perform ABO blood typing experiments in one step, the blood drop deposit, by agglutination of red blood cells (RBC) using embedded dried ... En savoir plus