Consultez les proceedings de la Conference COMSOL 2020

Fully Coupled FEM Modeling of the Swelling Behavior of Human Intervertebral Disc in Response to a Change in Chemical Environment

The swelling behavior of human intervertebral disc is strongly influenced by chemical changes in the surrounding environment. Swelling of IVD is governed by various physical phenomena, including chemical and electric potential based transport, electrical charge balance, and swelling due ... En savoir plus

Transport of Cadmium through Molten Salt to Argon Cover Gas in Electrorefiner

Electro refining is one of the important step in the Pyro processing nuclear spent fuel with molten salt. The electro refiner is a process vessel consists of anode ,cathodes and stirrers and ultra –high pure argon gas is provided at the top for inert atmosphere and at the bottom a ... En savoir plus

Numerical Investigation of Strouhal Frequencies of Two Staggered Bluff Bodies

A 2-D unsteady viscous flow around two cylinders is studied by numerical solutions of the unsteady Navier-Stokes equations with a finite element formulation using COMSOL Multiphysics®. The results of a numerical investigation of the Strouhal frequencies of two identical, stationary, ... En savoir plus

The Swelling Responsiveness of pH-Sensitive Hydrogels in 3D Arbitrary Shaped Geometry

The pH-sensitive hydrogels are responsive to the pH of surrounding solution, which often resemble to biomaterials. Recently, pH-sensitive hydrogels are widely used in various devices as sensing media. We present the simulation of swelling characteristic of 3D-arbitarary-geometry, pH ... En savoir plus

Equation Based Heat and Mass Transfer in Porous Media

Perspiration during intense physical activity is an essential part of human thermoregulation. Clothing affects the cooling rate of the body. Heat and water vapor are coupled through evaporation and transported through the fabric. A model of the above system was developed for fabrics of ... En savoir plus

3D Hydrogeological Modeling - From a Theoretical 2D Model through a Medium Scale Application up to a Challenge: Simulations at Basin Scale

An alluvial aquifer system has probably conceived as a numerical modeling hell. We have chosen COMSOL Multiphysics® for two reasons: 1) FEM methods allow to use complex geometries; 2) multiphysics simulation permits to run a single model with all phenomena. We built a section with these ... En savoir plus

Comparison Between Flow Simulations and Foam Experiments in Porous Media

Recovery of oil by gas injection is usually inefficient due to the low viscosity of the gas, which results in bypassing of the oil. By adding surfactant solutions it is possible to get in-situ foam formation. Foam has a much higher “viscosity” and hence does not bypass the oil, leading ... En savoir plus

Numerical Model for Leaching and Transporting Behavior of Radiocesium in MSW Landfill

This paper presents the numerical simulation model for radiocesium leaching and transporting behavior in municipal solid waste (MSW) landfill and discusses on the design for the required geometry and properties of the impermeable final cover and the soil sorption layer, which work for ... En savoir plus

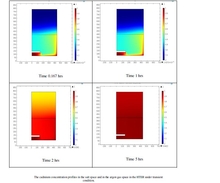

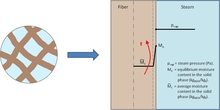

Modelling of the Wool Textile Finishing Processes

Within wool textile industries, a very important role is played by the so-called finishing processes, in which the textile substrate undergoes steam treatments to achieve the desired level of stabilisation and appearance. Process parameters, namely temperature and moisture content, are ... En savoir plus

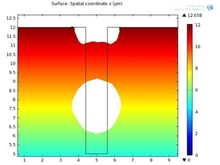

Void Shape Evolution of Silicon Simulation in COMSOL Multiphysics®

The void shape evolution of a trench patterned silicon substrate results in diverse cavities by varying initial conditions. The size and the arrangement of the initial trenches are decisive for the transformation process besides the annealing conditions which are, in fact, time and ... En savoir plus