Modeling a Lung-on-a-Chip Microdevice

Organ-on-a-chip microdevices combine microfluidics, MEMS, and biotechnology techniques to mimic the multicellular architectures, tissue-tissue interfaces, physicochemical microenvironments, and vascular perfusion of the body.[1] Such devices are being developed to provide better levels of tissue and organ functionality compared with conventional cell culture systems, and have great potential to advance the study of tissue development, organ physiology, disease etiology, and drug discovery and development.[1]

Modeling the multiphysics behavior of such devices is critical to their development and optimization. We have developed a COMSOL Multiphysics® software model of the lung-on-a-chip device of Huh et al.[2] that mimics the essential features of the blood-air barrier in human and animal lungs. The microdevice consists of a flexible membrane separating chambers for air and blood. Auxiliary vacuum channels enable stretching of the membrane to simulate breathing. Our model of the device makes use of the COMSOL methods for simulating fluid-structure interaction, nonlinear structural materials, laminar fluid flow, dilute species transport, and particle tracing capabilities.

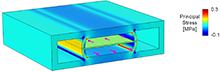

The lung-on-a-chip model shown in Figure 1 is based on Huh et al.’s device. Vacuum channels flank the midsection, which consists of an upper channel for air or cell culture medium and a lower channel for blood or cell culture medium. A thin 10 µm membrane separates the upper and lower channels. The PDMS membrane and walls are modeled with either neo-Hookean, Mooney-Rivlin, or Ogden nonlinear material models, parameter values for which are found in the literature.[3] A parameter sweep over vacuum pressures produces a strain-pressure relationship (Figure 2) useful for selecting a vacuum pressure waveform to deliver the desired membrane strain waveform. The selected vacuum pressure waveform is then used in a time-dependent simulation involving membrane and channel deformation and air/liquid flow (Figure 3). Additional features may be added such as particle tracing to model bacteria or particulate flow (Figure 4), drug or nutrient transport within the culture medium across the porous membrane, uptake by cells on the membrane, shear stress estimates on cells on the membrane, etc. Device function also may depend on manufacturing, material selection, and wear, for which such a model may also provide insight.

Téléchargement

- hancock_abstract.pdf - 0.45MB