Blistering of Industrial Floor on Concrete Substrate: the Role of the Air Overpressure

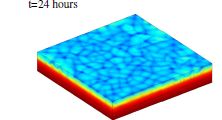

Surface coating can fullfil their function satisfactorily over an extended period of time only if there is a good bond between the concrete substrate and the coating. The most numerous cases of blistering affect the airtight covers of the concrete subjected to negative pressures of humidity from the support. The general objective of this study is the understanding of the blistering phenomenon. The migration of the water in the hardened concrete is made by capillary action and by diffusion of water vapour. When under face of the slab is in touch with some water, the concrete quickly stuffs itself with water, then the liquid/gas interface moves upward by compressing the air situated above the interface. The air pressure grows strongly when the material is close to the saturation. The comparison of numeric simulations realized with COMSOL Multiphysics with tests realized in laboratory throw some light on the role of the capillary pressure in the pressure developed in the concrete/cover interface.

Téléchargement

- devillers_paper.pdf - 0.43MB