La Bibliothèque d'Applications présente des modèles construits avec COMSOL Multiphysics pour la simulation d'une grande variété d'applications, dans les domaines de l'électromagnétisme, de la mécanique des solides, de la mécanique des fluides et de la chimie. Vous pouvez télécharger ces modèles résolus avec leur documentation détaillée, comprenant les instructions de construction pas-à-pas, et vous en servir comme point de départ de votre travail de simulation. Utilisez l'outil de recherche rapide pour trouver les modèles et applications correspondant à votre domaine d'intérêt. Notez que de nombreux exemples présentés ici sont également accessibles via la Bibliothèques d'Applications intégrée au logiciel COMSOL Multiphysics® et disponible à partir du menu Fichier.

A thin-walled metal frame with a central cutout, modeled using the Shell interface, is subjected to twisting and bending. Around the cutout the stresses are higher than the yield stress, thus the material undergoes plastic deformation over the loading history. En savoir plus

Ultrahigh Molecular Weight (UHMW) Polyethylene is a material commonly employed in knee and hip joint replacements. The “small punch test” is designed to assess mechanical properties using very small samples, such that because of their size they can directly be explanted. This example ... En savoir plus

In this example, a tensile test is simulated at four different strain rates. The Johnson–Cook hardening law is used to model the strain rate dependency of the plastic hardening. The temperature distribution and thermal expansion caused by the heating generated by the plastic ... En savoir plus

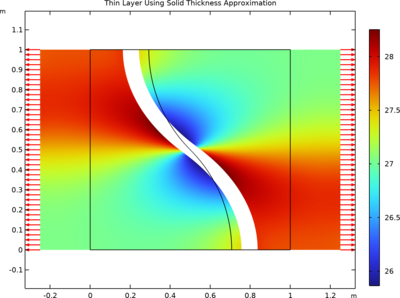

This model demonstrates alternative implementations used for describing a thin layer and the impact of the choice on the continuity of the displacement and stress fields. It is shown how a perfect interface can be obtained by asymptotically changing the material parameters. En savoir plus

In this tutorial model, it is demonstrated how to incorporate a localized nonlinearity in a submodel. In this case, an initial elastic analysis reveals that a small region of a structure has stresses above the yield limit. To improve the results, an elastoplastic material model is added ... En savoir plus

In this example, the Bergstrom–Bischoff material model is used to model the temperature and strain dependent behavior of High Density Polyethylene (HDPE) used, for example, to make liners for damaged pipes in oil and gas applications, or to make type IV hydrogen storage vessels for fuel ... En savoir plus

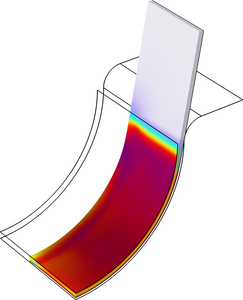

Die forming is a widespread sheet metal forming manufacturing process. The workpiece, usually a metal sheet, is permanently reshaped around a die through plastic deformation by forming and drawing processes. Simulations can be carried out in order to avoid cracks, tears, wrinkles, too ... En savoir plus

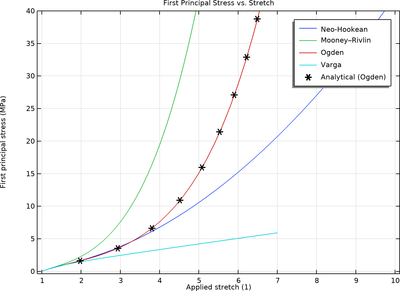

This model demonstrates the inflation of a rubber balloon with four different hyperelastic material models. The results are compared with the analytical solution for a thin-walled, spherical vessel. Controlling the inflation of hyperelastic balloons is important in clinical ... En savoir plus

The External Material functionality makes it possible to program your own material models for cases when the built-in material models are not sufficient. For structural mechanics, you have the possibility to either completely define the material model in a domain, or to add an inelastic ... En savoir plus

This example benchmarks a NAFEMS validation model of a friction contact problem with an elastoplastic material model. A thin metal sheet is forced into a die by a punch. Both the compressing displacement and the release of the punch are modeled in order to compute the forming angle (at ... En savoir plus