- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

At the Technische Universität Chemnitz several academic institutions work on aluminum matrix composites (AMCs) within the Collaborative Research Centre SFB 692 HALS. Besides the development and analysis of these materials one main task is finishing machining of AMCs by an electrochemical ... En savoir plus

Precise electrochemical machining (PEM) is a non-conventional machining technology, based on anodic dissolution of metallic work-pieces. In this study an additional extension of the precise electrochemical machining with a precise angle-controlled cylinder positioning is aimed. Due to ... En savoir plus

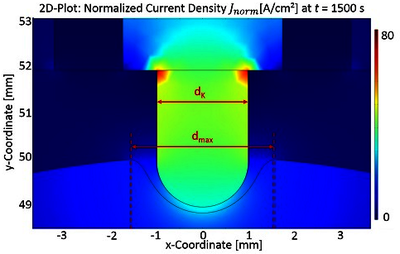

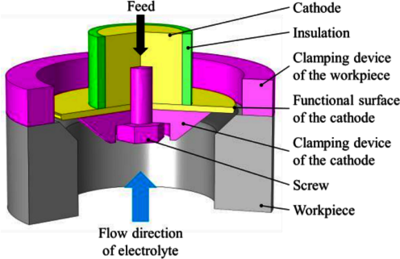

This study presents investigations on a developed process design for manufacturing internal precision geometries by pulsed electrochemical machining (PECM) with help of multiphysics simulations. Therefore, a 2D axisymmetric transient model was created. The considered physical phenomena ... En savoir plus

Precise electrochemical machining (PEM) is an innovative machining technology which results from further development of the electrochemical sinking. PEM works with pulsed low frequency direct current and oscillation of the tool electrode. As part of the project ‘Electrochemical machining ... En savoir plus

In the Collaborative Research Centre 692 at TU Chemnitz several academic institutions work on aluminum matrix composites (AMCs). These materials consist of an aluminum matrix, which is reinforced by SiC or Al2O3 particles with dimensions less or equal 1 µm. One main task is finishing ... En savoir plus

In this study the inverse Jet-ECM process of micro bores is investigated by help of multiphysics simulations. Based on the micro bore of a commercial sample nozzle a model geometry was derived. For simulating inverse Jet-ECM a transient model has been developed. Electric currents and ... En savoir plus

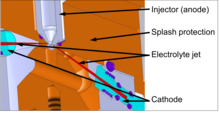

Jet Electrochemical Machining (Jet-ECM) is an unconventional procedure using localized anodic dissolution for micromachining. An increasing of the electrolyte temperature will lead to an increase of the electrical conductivity of the electrolyte by about 30% and to a reduction of the ... En savoir plus

Jet Electrochemical Machining (Jet-ECM) is an unconventional procedure for micromachining. Based on localized anodic dissolution three-dimensional geometries and microstructured surfaces can be manufactured using Jet-ECM. COMSOL Multiphysics is used at Chemnitz UT to simulate the ... En savoir plus

Evaporative cooling is a promising cooling method for dissipating high heat fluxes in high power density applications. One possibility to enhance heat flux is a generation of microstructures into the cooler surface. This enlarges the cooler surface and systematically affects the fluid ... En savoir plus

The principle of electrochemical machining (ECM) is the anodic dissolution of a metallic workpiece at the interface to a liquid ionic conductor under the influence of electric charge transport. This erosion principle works independently from the mechanical hardness of the workpiece and ... En savoir plus