- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal ... En savoir plus

Accurate tissue mechanical properties are essential for simulating medical devices that deform skin under suction, such as devices for the treatment of fat, skin wounds, and vascular skin conditions. While suction-based methods exist for estimating these properties, most rely on small ... En savoir plus

Simulation of laser processes are more and more efficient. In some cases, as welding and additive manufacturing, the physical phenomena are complex, multi-physics and multi-phases, thus some assumptions have to be done. For Laser Powder Bed Fusion, a laser beam melts and vaporizes the ... En savoir plus

Laser additive manufacturing has become an interesting field of engineering which is revolutionizing industrial processes. Selective Laser melting (SLM) is a widely used additive manufacturing technique for 3D printing of metal structures. This process has a particular complexity in ... En savoir plus

Laser assisted brazing with Al-Si fillers in V-shaped groove configuration is a perspective method for joining of aluminum alloys to titanium. The present work introduces multiscale model that allows estimating diffusion process at titanium/melted zone interface in function of thermal ... En savoir plus

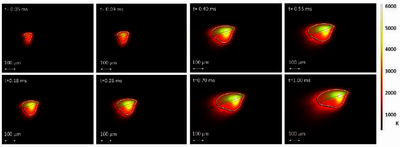

The formation of porosities in spot laser welding depends on complex thermo-hydraulic phenomena. To understand and control these mechanisms, the COMSOL Multiphysics® software is used to model both the interaction and cooling stages of an isolated impact made with a Nd:YAG pulsed laser. ... En savoir plus

Laser Welded Blank solutions enable to reduce vehicles weight and to optimize their crash performances by means of simultaneous tuning of different grades and thicknesses. The present work aims to characterize numerically and experimentally materials mixing during laser welding. For ... En savoir plus

Additive manufacturing technology is becoming more popular for the fabrication of metal products as it offers rapid prototyping and large design freedom. However, part quality of components fabricated by current additive manufacturing technology is not comparable to that produced by ... En savoir plus

A well-collimated intensity profile at long distance has long been a desired laser property crucial for many potential applications. Extending a non-diverging range for ordinary laser beyond kilometers scale would permit superior performance for optical technologies, including LIDAR, or ... En savoir plus

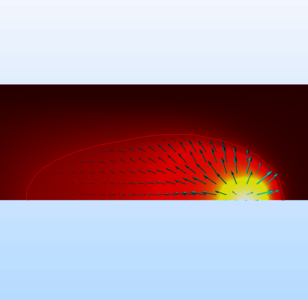

Time-dependent multiphysical simulation of pulsed and continuous laser welding of dissimilar metals, based on Moving Mesh (ALE) approach, is proposed. Strong coupling between heat transfer, laminar compressible flow and ALE is used. The model was validated for a case of single ... En savoir plus