- COMSOL News 2025

- COMSOL News Special Edition: Food Industry

- COMSOL News 2023

- COMSOL News 2022

- COMSOL News 2021

Keeping LEDs Cool Gets More Manageable Through Simulation

Aulis Tuominen and Mika MaaspuroUniversity of Turku

Turku, Finland

Toni Lopez

Philips Research

Eindhoven, The Netherlands

Sami Yllikäinen

Hella Lighting Finland Oy

Salo, Finland

Raimo Laitinen

Helvar Oy Ab

Karkkila, Finland

Light-emitting diodes (LEDs) offer many benefits over incandescent lighting, such as long life spans and high luminous efficiency, and they are environmentally friendly. One of the drawbacks, however, is that LEDs need to operate at the lowest possible temperatures and this must be carefully regulated.

Researchers at Business and Innovation Development Technology at the University of Turku in Finland have focused their attention on designing an efficient and inexpensive heat sink to regulate temperature. Simulation was crucial to their process as building prototypes is an expensive and time-consuming process.

Large manufacturing companies, such as Philips and Hella Lighting, use simulation to improve their LEDs as well. Simulation in COMSOL Multiphysics allows companies to determine the effect of new materials on the thermal behavior of the LED lighting device before a sample of that new material is even required for testing.

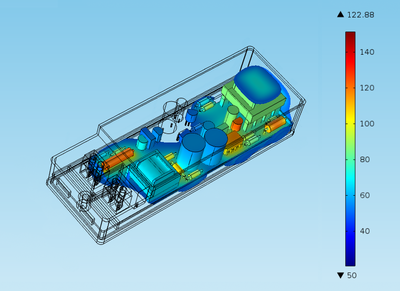

LED driver module simulation results where power dissipation in each component has been resolved by SPICE circuit simulation.

LED driver module simulation results where power dissipation in each component has been resolved by SPICE circuit simulation.

Téléchargement

- LED_Turku_MS2013.pdf - 1.56MB