- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

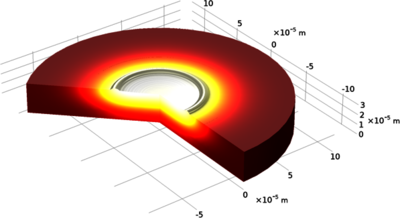

In the field of laser applications, surface treatment is highly studied. Two process categories are commonly used. First processes use very short pulses (femto or pico seconds) known to avoid thermal effects and to have high spatial resolutions. Second processes have higher interaction ... En savoir plus

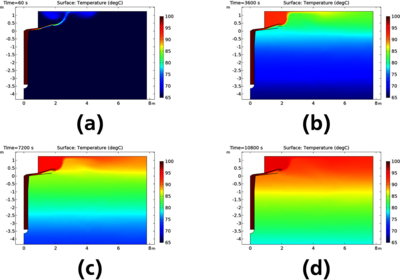

Small-scale short-term thermal energy storage (TES) systems and large-scale seasonal TES systems have been the focus of many research projects. However, large-scale short-term TES units have not been covered in great depth, even though they play an important role by decoupling the heat ... En savoir plus

Single droplet drying (SDD) is an established experimental set up in which an isolated droplet is dried under a controlled environment. The drying behavior in the SDD experiments is often complicated and challenged to observe. Hence, a robust model of single droplet drying can provide an ... En savoir plus

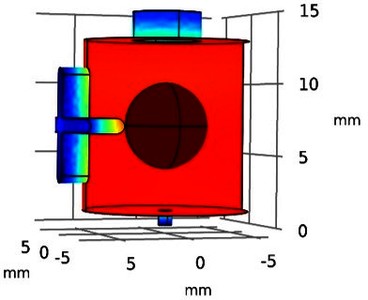

Interacting with digital devices has become part of daily life, whether in consumer products, services, or industrial applications. Most display-based devices provide user interactivity through touch sensing via a touch panel. As the number of device features increases, it demands an ... En savoir plus

The EPFLoop team from Lausanne last year won the 3rd place in SpaceX’s Hyperloop Pod Competition in 2018. This year the team will participate at the 2019 Competition held at the SpaceX facilities California. Reliability of the different subsystems constituting the pod is a key point. ... En savoir plus

Scientists and engineers have been designing and developing computational tools for the numerical simulation of heat transfer processes involving non-conventional heating or cooling effects for several years. Caloric effects rely on temperature variations upon external stimuli, e.g. ... En savoir plus

Material constants are required to develop new materials for the aerospace, automotive and energy industries. With these highly accurate experimentally determined data, complex metallurgical melting processes can be simulated later, for example. The microstructure of the new alloy can be ... En savoir plus

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. In this paper, the focus is on ... En savoir plus

The development of new experimental techniques designed to measure the thermal response of semiconductors at reduced length and time scales is revealing the requirement of generalized heat transport models beyond the classical Fourier law [1,2]. We present the Kinetic Collective ... En savoir plus

The efforts to integrate and/or expand the renewables into the overall energy scheme are drastically increasing in Europe. This integration might somehow alter the energy scheme resulting into shortcomings (e.g. security of supply is not met). Therefore, a number of strategies and ... En savoir plus