La Bibliothèque d'Applications présente des modèles construits avec COMSOL Multiphysics pour la simulation d'une grande variété d'applications, dans les domaines de l'électromagnétisme, de la mécanique des solides, de la mécanique des fluides et de la chimie. Vous pouvez télécharger ces modèles résolus avec leur documentation détaillée, comprenant les instructions de construction pas-à-pas, et vous en servir comme point de départ de votre travail de simulation. Utilisez l'outil de recherche rapide pour trouver les modèles et applications correspondant à votre domaine d'intérêt. Notez que de nombreux exemples présentés ici sont également accessibles via la Bibliothèques d'Applications intégrée au logiciel COMSOL Multiphysics® et disponible à partir du menu Fichier.

The powder compaction process is becoming common in the manufacturing industry, thanks to its potential to produce components of complex shape and high strength. In this example, the compaction of iron powder to form an axisymmetric rotational flanged component is analyzed with capped ... En savoir plus

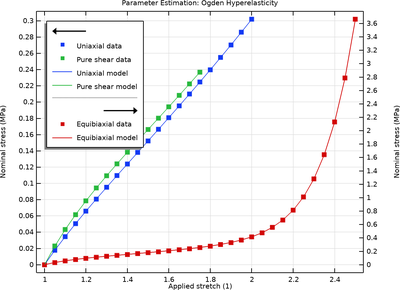

This tutorial model demonstrates how to set up a parameter estimation study for fitting the material parameters of an Ogden hyperelastic model to experimental data. The procedure considers multiple load cases under large deformations, which is often necessary to obtain constitutive ... En savoir plus

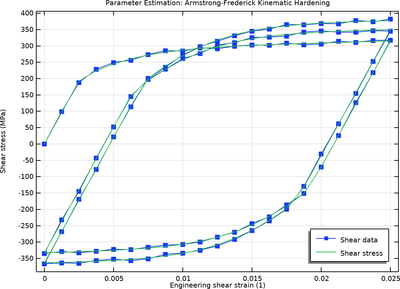

This tutorial model demonstrates how to estimate the material parameters of a combined hardening elastoplastic material model given cyclic shear data. En savoir plus

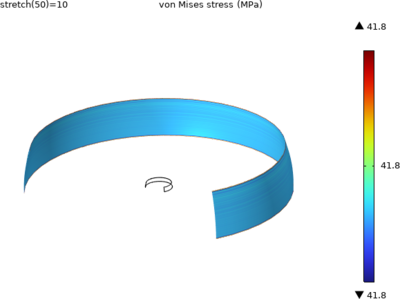

This version of the balloon inflation example demonstrates how the Shell and Membrane interfaces can be used to model thin structures made of hyperelastic materials. The example is identical to the Model Library model 'Inflation of a spherical rubber balloon', except that the Membrane ... En savoir plus

A stent is a wire-mesh tube used to open a coronary artery during angioplasty, a process for the removal or compression of plaque. Their design is of significance for percutaneous transluminal angioplasty with stenting. During this procedure, a stent is deployed into the blood vessel by ... En savoir plus

Stents are used in biomedical applications to support the inner wall of veins and arteries. Self-expanding stents made of shape memory alloys work differently from balloon-inflated stents, as these stents are crimped to the artery diameter at low temperature then released while the blood ... En savoir plus

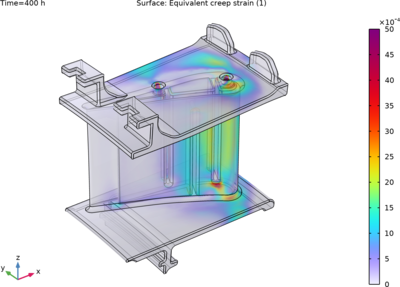

This example shows how to compute deformations caused by secondary creep in a turbine stator blade. The creep rate is highly influenced by temperature, and the deformation and stress relaxation is thus controlled by the temperature field. En savoir plus

This tutorial model demonstrates how to estimate the material parameters of a viscoplastic Bergstrom–Boyce model suitable for nonequilibrium modeling of rubber-like materials. The data used for parameter estimation consists of cyclic uniaxial tension and compression tests at two ... En savoir plus

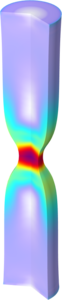

A circular metal bar is subjected to uniaxial tension. As an effect, large plastic strains develop. The material is elastoplastic with nonlinear isotropic hardening. As the elongation is increased, the decrease in radius becomes strongly nonuniform, so called "necking". The development ... En savoir plus

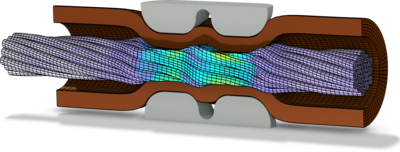

Crimping is the plastic deformation process used to form an electrical joint between a stranded conductor and a terminal. The process involves complex multi-surface contact, including self-contact, as the terminal sleeve is plastically deformed around the wire strands. This example ... En savoir plus