The Birefringence Change of Optical Fiber Polarizer with Fe-C Film in Corrosive Solution

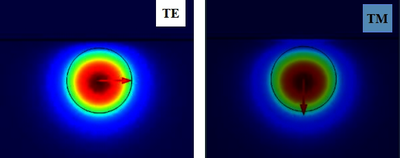

The detection of early corrosion is a key issue to mitigate the damage induced by metal corrosion. The optical fiber corrosion sensor based on a side-polished polarizer is realized recently. The polarizer is fabricated by sputtering a Fe film on a side-polished single mode fiber. The new fabricated polarizer is highly birefringent, which is confirmed by a theoretical model and experimental polarization characterization. This paper presents the simulation of the mechanism of the corrosion polarizer by using COMSOL Multiphysics®. Two 2D models are analyzed to compare the birefringence variation of a side-polished optical fiber (Model A) and Fe film coated polarizer (Model B), as shown in Fig.1. For Model A (without a metal coating), TE and TM modes are radiated through the polished surface with a loss at a same scale. Model B consists of Fe film and side-polished optical fiber. The flat surface of side-polished optical fiber is coated with Fe film. For Model B, TM mode is radiated out from the core into the metal film when it enters the interaction region due to the ohmic loss of metal film. And the TE mode light can propagate with lower loss in the fiber core. The extinction ratio (ER) is determined by the attenuation difference of TE/TM modes. The wave optics of the COMSOL Multiphysics® software was used to create the models of the polarizer under consideration. Electromagnetic Waves, Frequency Domain is used as physics interfaces. A scattering boundary condition is used to reduce the reflection from the boundary. The field distribution of the cross-section of the side-polished optical fiber coated with a Fe-C film is studied. The strengthes and leakage power of TE/TM modes are calculated. The ER value, which is the main parameter of the calculations, is derived according to the calculated power of TE and TM fields in the fiber core. By specifying the refractive index of coating layer to be Fe, Fe2O3 or surrounding media (i.e. no coating layer), different ER values can be obtained, as shown in Fig.2. The models with different coatings of various refractive indices are investigated to simulate the corrosion process and to build the relation between ER and corrosion evolution of Fe film. The result of the simulation reveals the corrosion of Fe-C film is related to the ER values, which is consistent with the experimental result. It turns out that the extinction ratio decreases during the corrosion process. The proposed polarizer can be used for monitoring the early stage of metal corrosion.

Téléchargement

- 袁_presentation.pdf - 1.03MB

- 袁_poster.pdf - 0.41MB

- 袁_abstract.pdf - 0.1MB