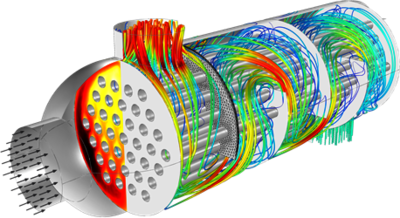

Shell-and-Tube Heat Exchanger

Application ID: 12685

Shell-and-tube heat exchangers are commonly used in oil refineries and other large chemical processes. In this model, two separated fluids at different temperatures flow through the heat exchanger, one through the tubes (tube side) and the other through the shell around the tubes (shell side). Several design parameters and operating conditions influence the optimal performance of a shell and tube heat exchanger. This model shows the basic principles of setting up a heat exchanger model. It can serve as a starting point for more sophisticated applications involving parameter studies or additional effects like corrosion, thermal stress, and vibration.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® et

- soit le Module CFD, ou Module Heat Transfer

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Grille des Spécifications and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.