Thermoelastic Damping in a MEMS Resonator

Application ID: 1439

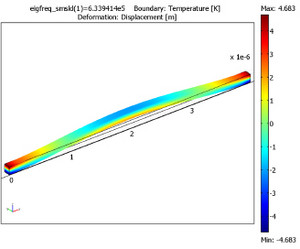

Thermoelastic damping, which arises when you subject a material to cyclic stress, is an important factor when designing MEMS resonators. The stress brings about deformation, where materials heat under compressive stress and cool under tensile stress. Thus, due to the resulting heat flux, energy is lost to bring about this damping.

The magnitude of the energy loss depends on the vibrational frequency and the structure’s thermal relaxation time constant, which is the effective time that the material requires to relax after an applied constant stress or strain. Therefore, the effect of thermoelastic dissipation, and consequently the damping, is most pronounced when the vibration frequency is close to the thermal relaxation frequency.

These models show how to model thermoelastic damping in a MEMS resonator using fully coupled thermal and structural mechanics equations.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® et

- soit le Module Heat Transfer, ou Module MEMS et

- soit le Module MEMS, ou Module Structural Mechanics

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Grille des Spécifications and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.