- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

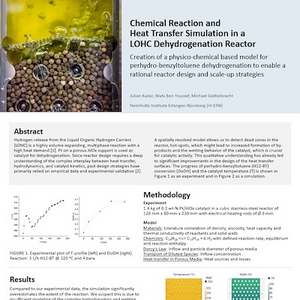

Chemical Reaction and Heat Transfer Simulation in a LOHC Dehydrogenation Reactor

The release of hydrogen from Liquid Organic Hydrogen Carriers (LOHC) is a highly volume-expanding, multiphase reaction with a high heat demand [1]. Platinum on porous alumina support is used as the catalyst for dehydrogenation. Since reactor design requires a deep understanding of the complex interplay between heat transfer, hydrodynamics, and catalyst kinetics, past reactor developments have primarily relied on empirical data and experimental validation [2]. This approach limits scalability, as holistic scaling demands a more detailed understanding of these coupled phenomena. By using COMSOL Multiphysics, we see an opportunity to explore new degrees of freedom in reactor design by integrating the individual physical and chemical effects into a comprehensive simulation model. The CFD, Chemical Reaction Engineering, and Porous Media Flow modules were used to build a model of the dehydrogenation reactor, employing suitable correlations to describe each phenomenon. The simulation offers valuable insights into the spatially resolved flow behavior within the reactor, allowing us to identify dead zones behind internal structures and the thermal interactions between close-by heated walls. This qualitative understanding has already led to significant improvements in the design of the heat transfer surfaces. The progress of reactant conversion is shown in Figure 1. However, compared to our experimental data, the simulation significantly overestimates the extent of the reaction. We suspect this is due to insufficient modeling of evaporation effects, which likely slow down the reaction and shorten the residence time once the reactants enter the gas phase. This issue stems from the highly dynamic three-phase system, in which the product gas phase becomes up to a hundred times more voluminous than the initially liquid LOHC phase. To address this, we are integrating more accurate effective heat transfer coefficients and chemical reaction kinetics, which we have recently determined experimentally at our institute [3, 4]. Still, a deeper understanding of the complex hydrodynamics inside the reactor may be essential for further improving the quantitative accuracy of the model. At this stage, we are looking to collaborate with experts from the COMSOL community who have addressed similar challenges and may offer insights or solutions.