Ressources

Livres Blancs

- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Comparison Between Honeycomb and Fin Heat Exchangers

Publié en 2011

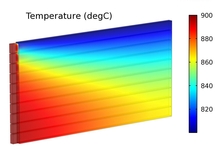

Metal honeycombs are used as catalyst supports. They can be considered as complex fins for heat exchange. A simple heat transfer model was compared with 2D simulations using COMSOL Multiphysics. There was a good correlation when the fluid temperature was the same in all cells. However, significant discrepancy apperared when compared with a 3D simulation with laminar flow.

Honeycomb cells produced a temperature gradient which reduced the heat transfer. The radiant transfer was also investigated using 2D simulation. Modeling using COMSOL revealed the drawbacks of using honeycombs in steam reforming reactors. 3D modeling showed that a careful representation of the inlet was needed for realistic results.

Téléchargement

- gateau_presentation.pdf - 1.8MB

- gateau_paper.pdf - 0.34MB