- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Cyclic Nonlinear Response of Soft Actuators for Surgical Applications

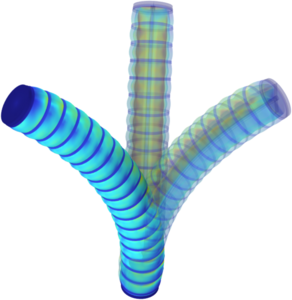

Soft actuators are poised to revolutionize the design of surgical and biomedical devices due to their unique adaptability and gentle interaction with biological tissues. A key challenge in these applications are the large deformations and repetitive cyclic loading during operation, which can lead to material fatigue, loss of function, or failure over time. Accurately predicting long-term soft actuator behavior is therefore critical to inform design strategies and material choices to mitigate property degradation and extend device lifespan. This study centers on a soft, flexible robotic endoscope designed for advanced surgical navigation (Figure 1). The endoscope is engineered to bend, twist, and maneuver through challenging anatomical pathways, granting access to difficult-to-reach regions in the body. The device considered incorporates three independently pressurized cavities, enabling precise multi-axis bending and nearly 360° coverage (see Figure 2) for enhanced dexterity and control during minimally invasive procedures. The behavior of the soft robotic endoscope is simulated using COMSOL Multiphysics®, leveraging the Solid Mechanics module, the Nonlinear Materials module and the Curvilinear Coordinates interface. This combination allows for precise representation of the device’s complex geometry and large deformations during actuation. To accurately capture the mechanical response of the endoscope, a calibrated hyperelastic-viscoelastic material model with Mullins damage is employed for the silicone rubber components. This advanced material model reflects the nonlinear, time-dependent, and damage-prone nature of silicone rubber under repeated loading and significant deformation. We calibrated the material parameters based on cyclic test data of the silicone material and Veryst Engineering’s expertise in polymer testing and modeling. This ensures that the finite element simulations provide reliable predictions for both the long-term durability and cyclic performance of the soft endoscope. The COMSOL model predicts the instantaneous response and long-term behavior of the endoscope after multiple actuation cycles (Figure 3). The cavity pressure time profiles, inputs to the model, and the resulting tip path are shown during a 360° actuation in the XY plane. The dependence of the tip motion on the pressure time profiles is a key performance metric for the endoscope. Such dependence may be tuned and optimized with our COMSOL model by varying both the pressure time profile and other design features such as the wall thickness distribution. By integrating advanced material characterization with state-of-the-art simulation tools, this modeling framework delivers robust insights into the endoscope’s mechanical behavior, such as the endoscope tip motion and its dependence on the cavity pressure time profile over repeated cycling. Such predictive capability is crucial for optimizing design, ensuring safety, and extending the operational lifespan of soft robotic surgical devices. As we showcase in this work, simulation can accelerate the design of soft actuators for biomedical applications, rapidly accelerating the evaluation and optimization of actuator geometry, material, and loading.