- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Effect of a wireless temperature/ pressure sensor location during in-packaged food microwave heating

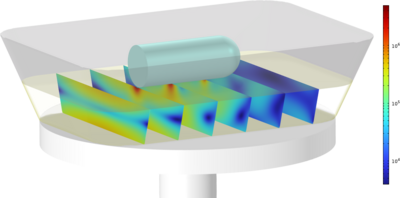

Pasteurisation and sterilisation are crucial thermal processes for insuring microbiological safety and stability of foods. In food industry, microwave (MW) heating enables to treat food products into their final packaging, thus limiting post-process recontamination. During the design phase of MW solutions, on-board MW sensors, integrated into the packaging, enable to evaluate the temperature (T) and pressure (P) in real time, two key parameters for in-package pasteurisation or sterilisation process of ready-to-eat meals. For process optimization objective, numerical modelling plays also an essential role in predicting the electromagnetic power dissipated locally within the food (Luan et al., 2016, Hong et al. 2021). This study focuses on a lab-scale 915 MHz MW heating process for mashed potato inside a polypropylene (PP) tray. The objective is to evaluate the influence of the position of an on-board wireless T and P sensor placed inside the PP tray on the electromagnetic field distribution within a single-mode MW applicator. Experimentally, the sensor (TMI Orion, PicoVACQ PT 15 Bar 4 Hz 3rd generation) is protected within a 316L stainless steel MW shield which looks like an ogive-shaped material (23 mm diameter, 58 mm long). The metallic shield is placed at the centre of the upper surface of the mashed potato sample (300 g) (figure 1D). COMSOL® Multiphysics 6.3 (RF module) is used to predict the electromagnetic field within the MW cavity associated with the MW absorbed power within mashed potato. The model takes into account all the geometrical details of the MW apparatus (waveguide transition, MW applicator with PP tray and metallic MW shield, sliding short circuit …). The microwave input power source (200 W) is modelled with a coaxial port (TEM mode) at the microwave antenna (port 1). All surfaces of the waveguide, including the copper sliding short circuit, are considered as perfect electric conductors (n × E = 0). The dielectric properties of mashed potato (75% water wet basis) are considered as constant with e’ = 45 and e’’ = 12 (issued from experimental measurements). For the solver settings, boundary mode analysis is used as a first step to compute the mode at port 2 that comes out of the waveguide (chimney beyond its height). The second step is a frequency stationary study at 915 MHz. Without sensor inside the tray, COMSOL® simulation reveals microwave reflected power of 24 % (S11 = -6.16 dB) with optimal sliding short circuit position at 790 mm (figure 1A). S11 is then evaluated as a function of varying MW shield positions following different z-axis rotations from alpha = 0 to 180° with 30° increment. Results indicate that S11 is fluctuating from -4.7 dB to -7.8 dB (33 to 17% MW reflected power). Figure 1C indicates that the MW shield position needs to be aligned to the MW propagation direction (alpha = 0°) to obtain similar S11 parameter as for the food tray without the sensor (S11 ≈ -6 dB). This numerical model helps to find the best position for the sensor to limit its interaction with the electromagnetic field.