Ressources

Livres Blancs

- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Modeling Residual Stresses in Arc Welding

Publié en 2010

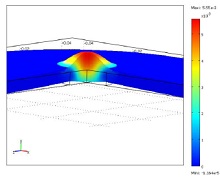

The prediction of mechanical response of assemblies during arc welding necessitates the knowledge of thermal history of the components and the constitutive behavior of the materials. COMSOL can simulate thermal and structural interaction but it needs to evaluate the time evolution of internal variables like viscoplastic strain and hardening parameters. In the present paper we extend the thermoelastic COMSOL model to thermoelastoviscoplasticity using Chaboche viscoplastic law with non linear kinematics and isotropic hardening with temperature dependence of model parameters. The model is used to describe the residual stresses evolution during welding of 316L stainless steel.

Téléchargement

- roger_presentation.pdf - 0.77MB

- roger_pres2.zip - 9.68MB

- roger_paper.pdf - 0.31MB