- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Modeling Water Immersion Thawing of Raw Tuna Fishes

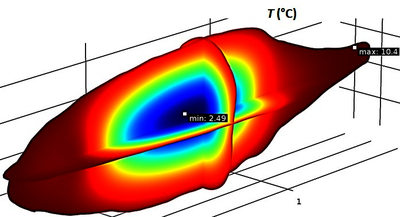

Thawing processes of raw tuna are widely used as a unit operation dedicated to the canning industry. At the industrial scale, the water immersion process remains the main relevant process for thawing large tuna fishes. The fish is then butchered and the flesh obtained is precooked before experiencing canning with sterilization. This thawing technique remains the longest unit operation and needs to be monitored to insure good product quality for further additional processes. In this work, the water immersion technique is studied from both experimental and modeling approaches to predict optimum thawing time and 3D thermal cartography within the fish. The main originality lies in the integration of Magnetic Resonance Imaging scans of a raw tuna fish and the 3D reconstruction of the real geometry from MATLAB® to COMSOL Multiphysics®. The numerical model consists in solving the transient heat transfer equation with phase change (apparent specific heat approach) within a 3D-generated mesh. Most important findings reveal that the model is able to predict accurately the experimental temperature profiles at different locations during thawing (from the head to the tail of the fish). For extrapolation purpose, several thawing scenario are proposed depending on the fish size for a constant ratio of perimeter contour at pectoral fins vs. total length. This numerical approach dedicated to industrial thawing of raw tuna fishes could significantly improve the process for a better optimization in terms of energy and water consumptions.

Téléchargement

- curet-ploquin_presentation.pdf - 2.68MB

- curet-ploquin_poster.pdf - 1.34MB

- curet-ploquin_paper.pdf - 0MB

- curet-ploquin_abstract.pdf - 0.08MB