Ressources

Livres Blancs

- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Modelling of the Temporal Analysis of Products (TAP) Reactor with COMSOL

Publié en 2008

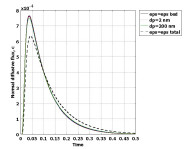

A TAP reactor is a fixed-bed catalytic reactor operated in pulse (transient) mode under very low pressures. It has become a very important tool in catalytic studies as it fills the material and pressure gaps existing between practical conditions and high vacuum – monocrystal techniques.

A pretreated solid catalyst maintained at a desired temperature in an evacuated chamber is exposed to a series of very narrow gas pulses.

COMSOL provides an easy way to model the results, particularly when dealing with non-standard experiments. COMSOL models can be converted to scripts and used as central parts of optimization programs for the determination of relevant kinetic constants.

Téléchargement

- Pietrzyk.pdf - 0.64MB