- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Modular Microjet Engine Technology

The modern microjet engine industry faces an ultimate constraint - a lack of physical platform for innovation, a need to completely develop new, existing technology to eventually test theory. Hence our proposal and development of a framework micro jet engine to be used as a platform for further research (prompted by the need to conduct our own) made possible by the modular design developed with goals of easy part swapping and rapid prototype testing. Our solution would come with exact specifications and geometry files for all standard parts to give the user essential information for the fabrication of their own. The main innovation to come from the engine is constrained only by a developer's budget and skill.

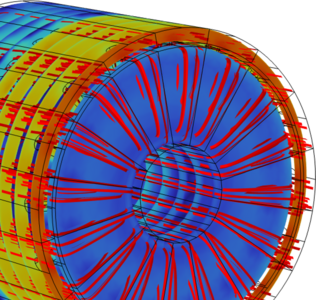

COMSOL multiphysics has allowed the completion of optimisation studies varying from the determination of best fuel to air ratio in a library of our adverse operating conditions, to the geometry of our combustion chamber and the effects of bleed air cooling on turbine inlet conditions. Originally fed by simple one-dimensional analysis, now growing from 2D approximation models into a cohesive, simulated system. As mentioned, our system will be made with easy disassembly in mind hence structural analysis is needed for all coupling and attachment methods. Further use of multiphysics will be completed for: the turbine stage via topology optimisation and compared with other software optimisation studies to validate results, also, in further projects regarding thermal management from the framework design, as well as vibration studies.

Our current operating conditions revolve around a mass flow rate of 1kg/s of air, aiming to produce 440 Newtons of thrust, made available by our: high efficiency optimized compressor and turbine geometries, high turbine inlet temperature and reduced mass compressor via a "pull away" starter motor. Currently we are working with the University of Manchester for prototyping and software licences, as well as NEMA Ltd. who we meet with biweekly to discuss our progress in a technical panel type manner. NEMA has expressed great interest in adapting our engine to test its magnetic bearing systems for turbomachinery - one example of how our framework could be used in industry.

The project is now in meticulous stages of development essentially combining all goals whilst attaining safety factors and work beginning on final design jobs: test rig (structurally verified in COMSOL), data loggers and fuel storage / pumps that avoid corrosion or coking. Eventual application of the technology may reside in commercial and military sectors; the framework idea will also act as an upgradable, easy to maintain system in aircraft - allowing iterations of technology without the manufacture of a new fleet, but for example new compressors. We aim to deliver a preprint and final draft paper on this project however await manufacturing and testing.