- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

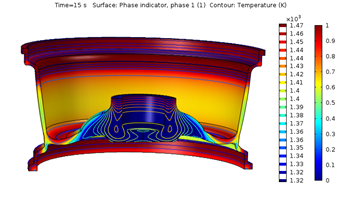

Multiphysics CAE Simulations of Casting Process for First-time-right Product Development

Casting product performance depends on material, flow, Process Temperature, Solidification, Shrinkage and residual stress. In a casting process, not all available resources are utilized effectively which results in low quality of casting, defects and metal wastage. Physics based modeling is increasingly used to optimize product performance, improve quality and reduce defects of casting products. In this poster phase change solidification process of alloy wheel is investigated for process performance and optimization. Here COMSOL Multiphysics software with the Heat Transfer Module with Phase change physics is used. Coupled flow, heat transfer and phase change solidification process modeling of casting process will enable first time right casting product development. This study will be further used to predict the properties profile of the casted parts.

Téléchargement

- hussain_poster.pdf - 0.42MB

- hussain_paper.pdf - 0.48MB

- hussain_abstract.pdf - 0.05MB