- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Numerical modelling of slot die coating

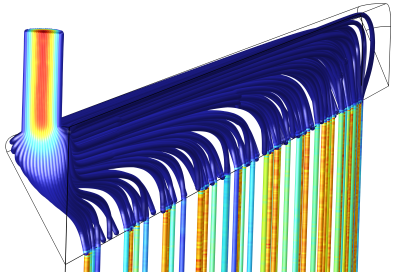

Slot die coating is a method to apply thin films of materials on a substrate. The geometry of the die affects the flow of the material within it and the quality of the layer being deposited. The die can also be blocked along the width for multiple parallel depositions or to deposit on narrower substrates. In addition, solutions with particles in suspension behave as a non-Newtonian fluid where the viscosity changes as function of the shear rate, with particles that can settle over time negatively affecting the quality of the deposited layer. COMSOL Multiphysics® was used to carry out a stationary study (Study 1) to investigate the fluid flow within the die for different fluid rheology. The geometry of the die was directly created in COMSOL Multiphysics®. The model takes advantage of the symmetry of the die, allowing the user to model half of it along its width. The exit of the die is blocked at the two far ends. The rheology for the non-Newtonian solutions was implemented using an interpolation function. The Laminar Flow interface was then used to simulate the flow. Within it, fluid properties and mass flow rate at the inlet were defined.

COMSOL Multiphysics® was also used to estimate the residence time of the solution within the die. To this end, a time dependent study (Study 2) was run to solve the Particle for Fluid Flow interface for a time length of three hours. Within the interface, particles were considered massless and their velocity sourced from the fluid flow solved in Study 1.

Results show that Pressure drop is caused mainly by the flow through the narrowest section of the die, the shim, and it also depends on the rheology of the fluid.

Visualisation of streamlines coloured by the residence time variable showed high residence time at the extremity of the die where the manifold is blocked. The residence time distribution and cumulative distribution show that 95% of the particles reach the outlet of the die after 500s.

This model represents tool to investigate the combined effect of the rheology of the fluid and the geometry of the die on the behaviour of the fluid within the die. This is extremely valuable to select solutions and geometries to get right first-time deposition.