- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Simulation of a Multicomponent Trace Gas Electric Swing Adsorption

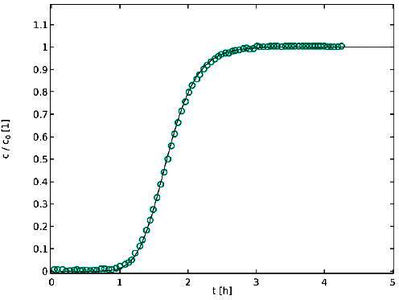

Introduction: Electric swing adsorption is a promising technique for energy efficient gas cleaning and adsorbate recovery. Contrary to state of the art temperature swing and pressure swing adsorption, one can control the mass flow independently of the heat flow for desorption in an electric swing adsorption. The scope of this work is to model the electric field, the resulting heat flow, the gas flow in a porous medium and the multicomponent intraparticle adsorption. As an industrial relevant example, the gas cleaning of a coke oven gas stream from catalyst poisons is simulated employing three adsorbing components competing for the vacancies. Modeling and Simulation: Within a two dimensional rotationally symmetric geometry, the Electric Currents physics interface is set up to model the electric field and current between two electrodes. Using the predefined multiphysics coupling, the joule heating of the apparatus is considered. The resulting heat source is embedded in the Heat Transfer in Solids. Additionally, the Heat Transfer in Fluids interface is used to respect the heat flux of the fluid. For mass conservation, the Transport of Diluted Species in Porous Media physic interface is used since the properties of the fluid mainly depend on the inert components that make up the majority of the mole stream. The velocity profile is set up as a plug flow. Within this physic interface, the reactive pellet bed feature is used to build an extra dimension for the activated carbon particles. Inside of the particles the mass transport and the equilibrium reaction of the adsorbate is considered. The Chemistry physic interface is applied to model the adsorbate formation as an equilibrium reaction. The temperature and concentration dependent equilibrium coefficients are calculated externally and stored as an interpolation. The simulated apparatus is 0.5 m long and has a diameter of 0.2 m; the particles have a diameter of 1 mm. The feed gas has a typical coke oven gas composition in which three trace gas components are considered as adsorbates, while the other five components are treated as inerts. The time dependent adsorption and desorption cycles are set up via the Global ODEs and DAEs and the Events interfaces respectively periodic functions. Results and Conclusions: For multicomponent mixtures, competitive adsorption was expected. The results of the simulation clearly show the anticipated behavior of the adsorbates. Therefor it is concluded that the novel application of the externally calculated equilibrium coefficients for the adsorption reactions is a correct description for this scenario. Additionally, the multiphysical model involving an electric field, joule heating, solid/fluid heat transfer and intraparticle mass transport is successfully utilized to picture an electrothermal desorption. The simulated mass transport is validated at different sources. The form of the adsorption isotherms allow you to predict the form of the concentration fronts during ad- and desorption. In addition, literature data from a binary breakthrough experiment involving competitive adsorption was used to validate the model at hand.

Téléchargement

- geitner_presentation.pdf - 1.11MB

- geitner_paper.pdf - 0.3MB

- geitner_abstract.pdf - 0.02MB