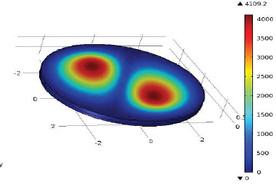

- Bridging the Terahertz Gap

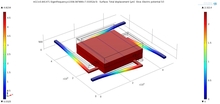

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

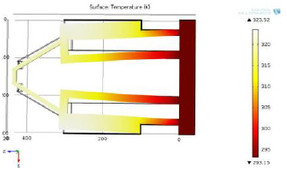

- Modélisation thermique des petits satellites

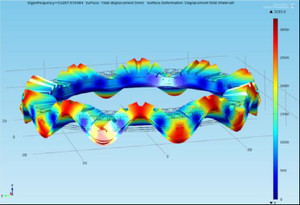

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

COMSOL Conference 2025 Proceedings

Collection of Papers, Posters, and Slideshows Accepted by the Program Committee

À la conférence COMSOL 2025, des ingénieurs, des chercheurs et des scientifiques du monde entier ont présenté leur utilisation de la modélisation et de la simulation dans tous les grands secteurs d'activité et dans le monde universitaire. Utilisez l'outil de recherche rapide pour trouver une présentation spécifique ou filtrez par sujet ou par lieu d'événement.

ISBN: 978-1-7364524-3-1

Microgrippers are typical MEMS devices used to pick, hold and transport micro-objects. Microgrippers are widely used in the field of micro-assembly, micro-surgery and manipulation of micro-particles. Thermal microgrippers are widely used for large displacement, high accuracy and ... En savoir plus

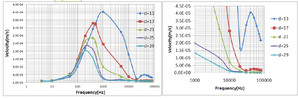

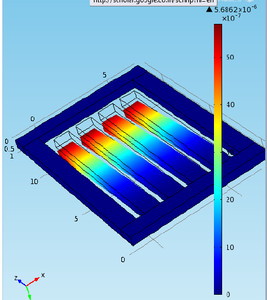

This paper discusses the simulation studies on a vibration based energy harvesting system to convert the undesirable mechanical vibration to useful green power. The design consists of a resonating proof mass and a spring system enclosed in housing and fixed on the source of vibration. A ... En savoir plus

In this paper some discrete parts of a valveless piezoelectric micropump for drug delivery system is designed and simulated. The core components of the micropump are actuator unit that converts the reciprocating movement of a diaphragm actuated by a piezoelectric actuator into a pumping ... En savoir plus

Micro machined motors are a recent development in the domain of electrical machines. Compared to the conventional electromagnetic motors, micro machined motors offer high torque at lower speed, and are compact in nature. This makes them suitable for applications in the field of ... En savoir plus

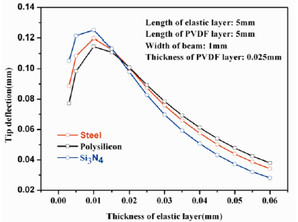

Cantilever beam-type transducers have been in great demand and explored widely in the recent years, typically in thin film form because of their sensor and actuator applications. The piezoelectric cantilever is the most preferred structure employed in technological applications. ... En savoir plus

Micro-grippers find applications in micro-robotics, microsurgery, micro-fluidics, micro-relays, assembling and miniature medical instrumentation. Actuation principle involved may be electrothermal, electrostatic, piezoelectric, shape memory and electromagnetic. It has been found that ... En savoir plus

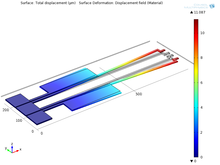

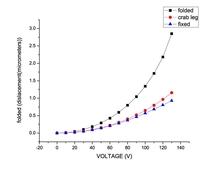

A new design of electrostatic comb drive actuator is presented in this paper by using different spring designs and with different folded beam lengths. An increased displacement of lateral comb drive actuator will subsequently be accomplished with the same actuation voltage. Stress ... En savoir plus

Electrokinetic transport of fluids has been investigated both experimentally and numerically due to its various applications in microfluidic devices [1-5]. These devices offer the advantage of transporting fluids or particles to specific locations without the aid of mechanical ... En savoir plus

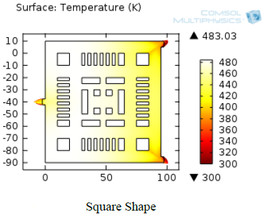

Micro-Heaters are the key components in sub-miniature micro-sensors, especially in gas sensors. The metal oxide gas sensors utilize the properties of surface adsorption to detect changes in resistance as a function of varying concentration of different gases [5]. To detect the resistive ... En savoir plus

The paper brings out the designing and implementation of blood viscosity monitoring device that gives us the INR to measure the effectiveness of anti coagulant medications .When a blood vessel is damaged, clotting cascade begins that results in blood clot. This process is affected by ... En savoir plus