- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

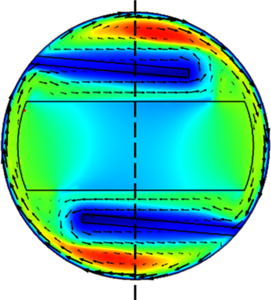

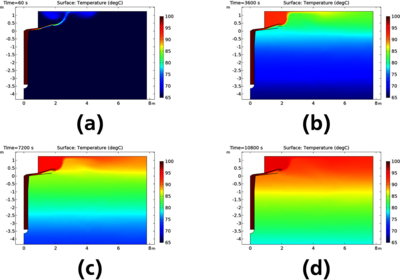

Scraped-surface heat exchangers (SSHEs) handle products that are viscous, that contain particles, and that tend to deposit on the heat transfer surface. The rotating scraper blades continuously remove any deposition on the heating or cooling surface, thereby maintaining the efficiency of ... En savoir plus

Irradiance is fundamental in the energy production of photovoltaic (PV) modules and models can be developed using just irradiance data. However, module temperature has also significant impact on the power output. In locations with high ambient temperatures PV module performance can be ... En savoir plus

New emerging trends in the MEMS market are linked to the availability of small, reliable and miniature sensors for harsh environment applications to increase penetration in all application fields, considering very wide operating condition ranges. These trends are pushed forward by the ... En savoir plus

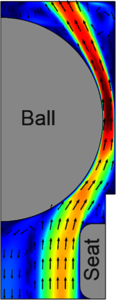

Motivation We simulate the fluid driven interaction between two dynamically coupled valves designed to work in conjunction with each other. Such interacting valves are extensively used in sucker rod pumps for oil extraction. These pumps essentially consist of a pair of ball check valves ... En savoir plus

Contact angle hysteresis is an important physical phenomenon, it is an essential parameter in wetting and capillarity, and it plays an important role in many industrial processes, especially in Enhanced Oil recovery (EOR). In this paper, the contact angle hysteresis (CAH) of ... En savoir plus

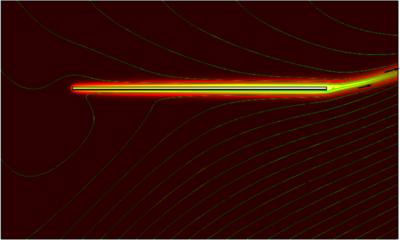

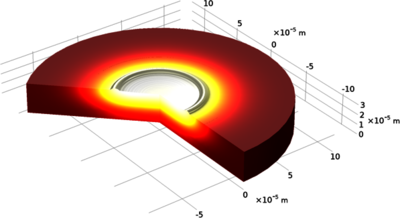

In the field of laser applications, surface treatment is highly studied. Two process categories are commonly used. First processes use very short pulses (femto or pico seconds) known to avoid thermal effects and to have high spatial resolutions. Second processes have higher interaction ... En savoir plus

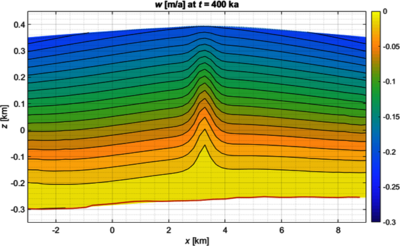

Ice flows because at low stresses it deforms viscously; the viscosity depends upon the stress. The lubrication approximation (LA) states shear stress is proportional to the product of the ice depth and surface slope. At ice divides the slope and shear stress are zero meaning the ... En savoir plus

Small-scale short-term thermal energy storage (TES) systems and large-scale seasonal TES systems have been the focus of many research projects. However, large-scale short-term TES units have not been covered in great depth, even though they play an important role by decoupling the heat ... En savoir plus

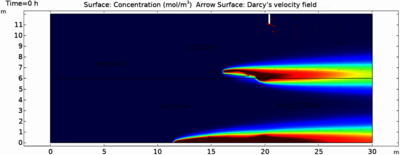

The presence of anthropogenic or natural pollutants in groundwater system poses a threat to water resources. Several remediation techniques have been explored and developed to decrease the concentration of contaminants. One such remediation technique, injection of nano-particles in the ... En savoir plus

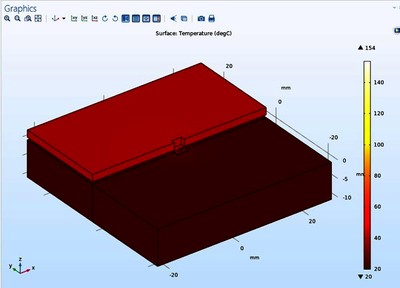

During semiconductor manufacturing, finished silicon microchips need to be released from a carrier tape they stick to by an adhesive. This is done by vacuum forces that (a) hold the chip flat from above and (b) pull the tape off from the chip underside. Sounds simple, but is very tricky ... En savoir plus