- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

This work, which is done in the framework of the SisAl Pilot EU project, presents the use of the COMSOL Multiphysics® software for simulating an ensemble averaged electric arc in a laboratory-scale electric arc furnace. The SisAl Pilot project aims at optimising the silicon production in ... En savoir plus

A numerical model of laser welding process applied on highly optically reflective and thermally conductive materials such as copper has been developped. The latter considers multiphysical couplings of CFD, heat transfers and phase-field representation to account for topological ... En savoir plus

The vacuum arc remelting is a refining process used to melt reactive metals like titanium, zirconium or hafnium. Melting is performed under vacuum to avoid reactions between liquid metal and oxygen which could be a source of pollution. This process is particularly well suited to purify ... En savoir plus

In the nuclear industry, and particularly at Framatome, mastery of welding processes is essential. Framatome is one of the world leaders in this field and wants to improve even more. The work presented focuses on improving the TIG (Tungsten Inert Gas) welding process, and more ... En savoir plus

The present work introduces a new methodology, based on COMSOL Multiphysics® Application Builder, to account for the “beam trapping” effect in multiphysical modelling of laser welding. Incident intensities involved in laser welding processes are high enough to induce material ... En savoir plus

In order to improve the design of an induction furnace and to optimize the charge melting, a COMSOL Multiphysics® application is developed. This application runs a furnace model. The inductor, supplied with an alternative electrical tension, creates a variable induction field B ⃗. Due to ... En savoir plus

Laser cladding is an additive manufacturing process, where a laser beam creates a melt pool, into which powder is fed from a powder nozzle. Due to the feed motion of the laser beam and the powder nozzle relative to the workpiece, coatings and 3D parts can be deposited, which consist of ... En savoir plus

Currently in the semiconductor industry more than 80% of silicon crystal are grown by the Czochralski (Cz) method. In this method, fused silica (SiO2) crucibles and graphite heaters are used inside furnaces. The surface of the crucibles, which are in contact with the molten silicon, is ... En savoir plus

The heat and fluid flow calculation inside the melt pool in welding processes is a complex challenge. It can be useful to predict defects in the weld seam or to study the influence of some process parameters. Even if the required equations are mastered over the last few years, the cost ... En savoir plus

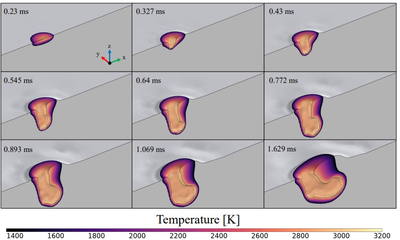

Laser metal deposition is widely adopted for coating, reparation and 3D printing. Using COMSOL, we have developed a numerical model with full coupling of laminar fluid flow and heat transfer. The Marangoni effect is considered to capture the enhanced convective heat transfer as well as ... En savoir plus