- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

The initiation in numerical modeling of welding with COMSOL Multiphysics® is proposed to the 2nd year students of the professional master program «Processes, Controls, Metallic Materials: Nuclear Industry» (PC2M) of University of Burgundy, France since 2016 within the module «Simulation ... En savoir plus

Arc current welding is a widespread process in heavy industry for the assembly of metallic components. In order to ensure the good quality of assemblies welds, it is appropriate to master the welding process but also to have a deep understanding of interactions with the weld pool and ... En savoir plus

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. The objective of the work presented in ... En savoir plus

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. The objective of the work presented in ... En savoir plus

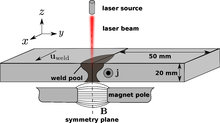

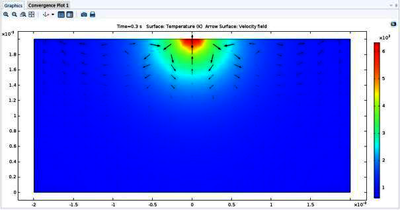

The article deals with the magnetically-supported high-power full-penetration laser beam welding of aluminum. A stationary simulation was conducted accounting for the effects of natural convection, Marangoni convection and solid-liquid phase transition as well as an electromagnetic ... En savoir plus

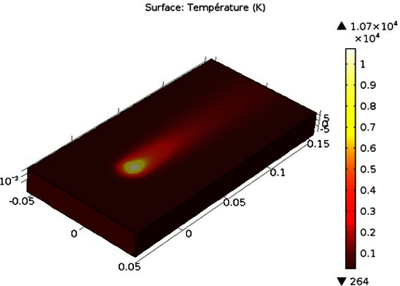

Laser additive manufacturing has become an interesting field of engineering which is revolutionizing industrial processes. Selective Laser melting (SLM) is a widely used additive manufacturing technique for 3D printing of metal structures. This process has a particular complexity in ... En savoir plus

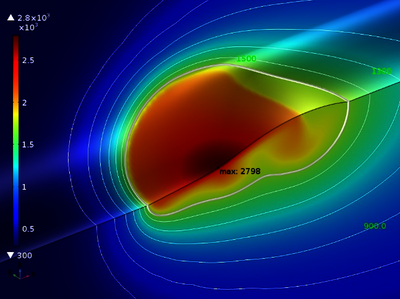

Laser welding is often considered to be a superior technique over different conventional welding methods and has been gradually evolved as an efficient manufacturing process. It is a high energy density fabrication process and generally employed for fabricating intricate shapes/contours ... En savoir plus

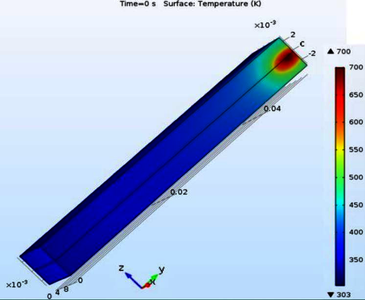

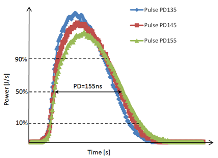

It is now a well known that the next generation devices in many fields of the semiconductor industry will be based on 3D architectures. In this framework, low thermal budget annealing technological solutions are required. For many applications, either in the field of sensors, ... En savoir plus

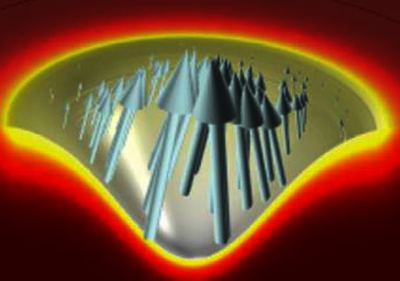

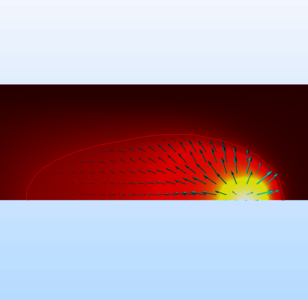

Marangoni flow affects the heat and mass transfer occurring in the molten metal regions in welding and additive manufacturing processes. It originates from the surface tension gradient (∂γ/∂T) induced at the melt pool surface due to the temperature difference. The flow pattern within ... En savoir plus

The Laser Metal Deposition process (LMD) is a rapid free form fabrication method which can be used to manufacture new near net shape metallic components, to repair used ones or to add functional parts on existing ones. This process is composed by multiple gas streams flowing inside a ... En savoir plus