- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

The "Power to Gas" technology is a promising alternative for storing renewable electrical energy through energy carriers. This technology involves using surplus energy from renewable sources to obtain green hydrogen through water electrolysis. Since hydrogen storage and transportation ... En savoir plus

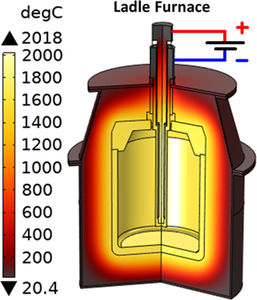

This work, which is done in the framework of the SisAl Pilot EU project, presents the use of the COMSOL Multiphysics® software for simulating ladle furnace preheating. The SisAl Pilot project aims at optimising the silicon production in Europe by recycling materials and using a carbon ... En savoir plus

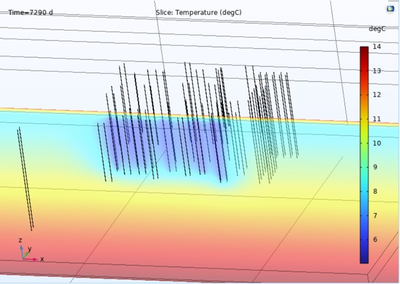

Transforming the energy sector worldwide towards renewable, climate-neutral energy sources requires innovative ideas and excellent engineering solutions. In particular, shallow geothermal energy utilization is currently showing a remarkable development. In highly urbanized regions, large ... En savoir plus

Historically, indoor air quality (IAQ) has received less attention than outdoors, although people spend >90% of their time in the indoor environment. A major group of indoor air pollutants is volatile organic compounds (VOCs), which are detrimental to human health even at low ... En savoir plus

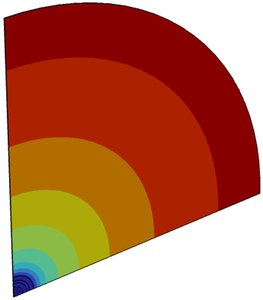

Geological repository for highly radioactive waste disposal is a system of engineered and natural barriers. The objective of this system is to contain and isolate waste and protect the environment and humans from ionizing radiation. For the evaluation of performance of engineered ... En savoir plus

In this study, we attempted to develop a simulation to better understand the kinetic of the dye regeneration process in photoanodes of dye-sensitized solar cells (DSSCs). For that purpose, a numerical model was developed using finite element simulation in COMSOL Multiphysics®. The ... En savoir plus

The study of bentonite erosion mechanisms in fractures is a problem of maximum interest to understand the long-term performance of the engineered barrier in deep geological repositories of spent nuclear fuel. In this context, erosion due to shear by seeping water, sedimentation due to ... En savoir plus

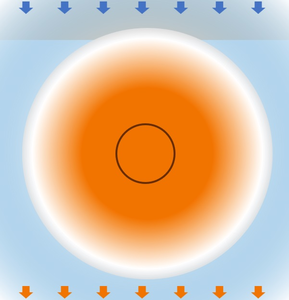

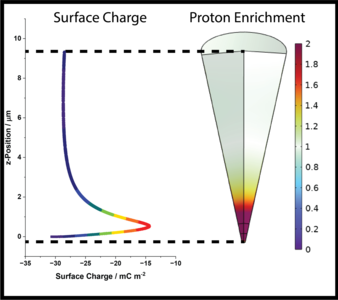

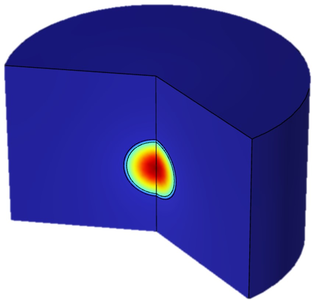

The acid-disassociation of surface groups generates the surface charge that drives fundamental nanoscale ion transport behaviors, such as ion current rectification in nanopores. Ion current rectification can be utilized for high sensitivity label-free sensors. The disassociation of ... En savoir plus

In the construction sector, the concrete and the steel bars represent still the key components, although they are very vulnerable by the atmospheric agents, as in the case of their degradation caused by corrosion. The value of the concrete carbonation may enhance the corrosion around the ... En savoir plus

Currently, there is a great interest in the study of gels, especially their transport or release properties. Hydrogels have countless definitions, but generally speaking, they are hydrophilic systems with a three-dimensional structure that tend to swell and hold large amounts of water ... En savoir plus