Pitting Corrosion in Stainless Steel

Application ID: 144581

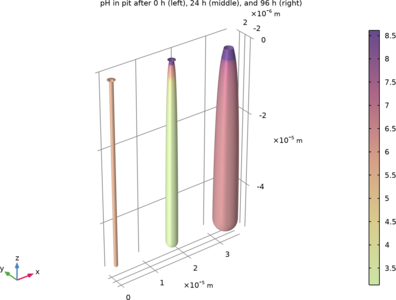

Pitting corrosion is localized corrosion by which local cavities, pits, are formed on a seemingly initially smooth metal surface. A pit may be initiated due to small surface defects, such as inhomogeneities in composition or shape, or from mechanical abuse.

How and if the pit grows depends on its shape and type of metal together with on a number of electrolyte factors such as salinity, pH, and temperature. Understanding the pitting process is paramount for proper material selection in corrosive environments.

This tutorial investigates the fundamental mechanisms of pit propagation by simulating electrode kinetics, mass transfer, and the resulting geometry deformation in a common type of stainless steel.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® et

- soit le Module Battery Design, Module Corrosion, ou Module Electrodeposition

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Grille des Spécifications and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.