- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

A photoelectrochemical (PEC) cell uses solar energy to split water to hydrogen and oxygen in single integrated device. Electrochemical impedance spectroscopy is a suitable tool to characterize recombination and reaction mechanisms in PEC cell. Full numerical drift-diffusion calculations ... En savoir plus

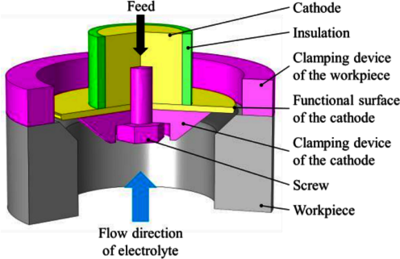

This study presents investigations on a developed process design for manufacturing internal precision geometries by pulsed electrochemical machining (PECM) with help of multiphysics simulations. Therefore, a 2D axisymmetric transient model was created. The considered physical phenomena ... En savoir plus

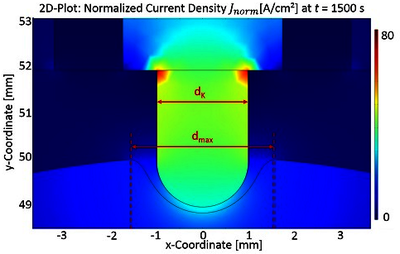

Precise electrochemical machining (PEM) is a non-conventional machining technology, based on anodic dissolution of metallic work-pieces. In this study an additional extension of the precise electrochemical machining with a precise angle-controlled cylinder positioning is aimed. Due to ... En savoir plus

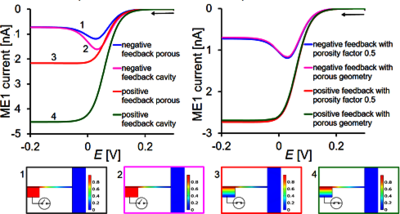

In the past two decades, highly porous nanostructured materials have been investigated and used for a large variety of applications, such as catalysis, energy conversion/storage, optics, sensing and more. Nanoporous gold (npAu) is one of such materials which have shown great potential as ... En savoir plus

This work is a first evaluation of the validity of the frozen rotor approximation for the simulation of a stirred beaker. The agreement is good, further analysis will be carried before using the model to optimize labscale setup dedicated to IL electrochemistry. En savoir plus

During the basic operation of a lithium-sulfur (Li-S) cell, sulfur molecules are required to undergo a complex mix of electrochemical and chemical reaction processes. To date, almost all modeling of Li-S cell behavior has been undertaken using electroneutral, structurally homogenized, ... En savoir plus

This work aims at the modelling of a 5 cm^2 Direct Methanol Fuel Cell (DMFC) with mixed serial/parallel serpentine flow fields in terms of current/voltage behavior. One of the main challenge to overcome consists on lowering the so-called methanol cross over from the anode through the ... En savoir plus

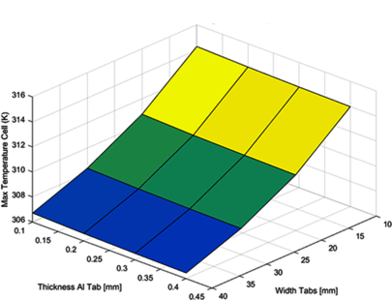

OXIS Energy Ltd is a pioneer in the research and development of Lithium Sulfur batteries. Scaling up from R&D level coin cells to pouch cells for automotive use, engineering design and thermal management start to become critical. In this study, heat flow at various levels of the cell ... En savoir plus

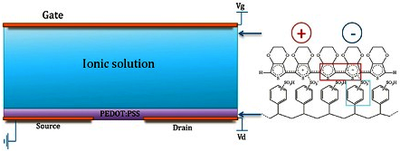

One of the most promising categories of semiconductor-based sensors is organic electrochemical transistor (OECT), which consists of three electrodes (Source, Drain and Gate) and two active layers: electrolyte and conductive polymer. Despite the fact that OECT attracts a lot of attention ... En savoir plus

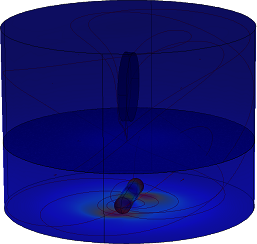

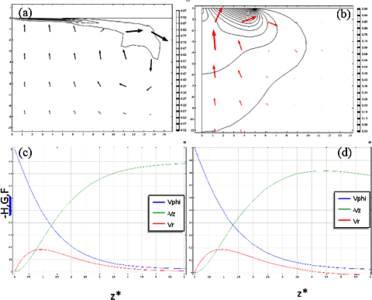

In this work we report a numerical model of a Rotating Disk Electrode (RDE) voltammetry in a finite size domain. Thus, explaining the discrepancy of the diffusion coefficient obtained from the experimental rotating speed, with respect to the literature data. We achieved a very good ... En savoir plus