- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

As in industrial countries, people spend most of their time indoors and the stringent heat-insulation measures in combination with deficient ventilation have a negative impact on indoor air quality, one approach for abating indoor air pollution is the integration or retrofitting of a ... En savoir plus

Methane detection and quantification is of great importance due to its natural abundance, potential to cause explosions and known greenhouse effect. Leak detection and concentration monitoring at source is highly challenging as CH4 is odorless and colorless. This can be performed ... En savoir plus

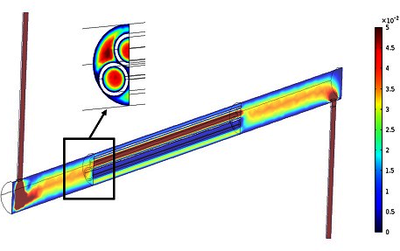

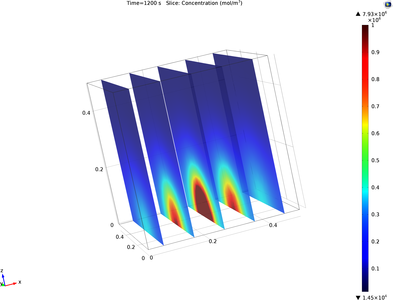

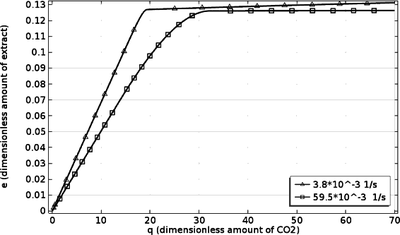

This paper shows the solution of mathematical model of supercritical fluid extraction process, given by Sovova H., 1994, through COMSOL Multiphysics® software. Sovova et al., 1994 used this model for the supercritical CO2 extraction of grape seed. Extraction was performed with different ... En savoir plus

In the present work, COMSOL Multiphysics® software was used to solve a mass transfer based mathematical model (Stastova et al., 1996) which is a modified form of Sovova H.,1994 model. The modification has been brought about by introducing the term ‘Grinding efficiency’ in the model and ... En savoir plus

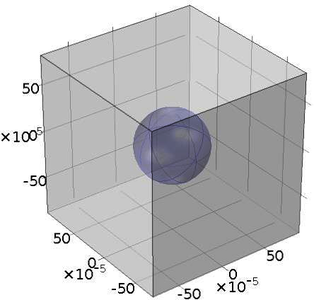

Reaction-Diffusion equation is simulated for heterogeneous catalytic reaction involving a porous catalyst particle surrounded by liquid reactants. COMSOL Multiphysics® software along with transport of dilute species module is used for this purpose. Global Variables such as reaction ... En savoir plus

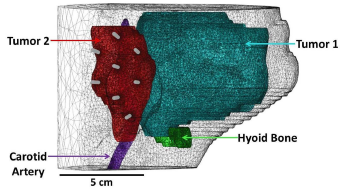

Interstitial photodynamic therapy (I-PDT) can be applied for the treatment of locally advanced head and neck squamous cell carcinoma (LA-HNSCC). The complex anatomy of LA-HNSCC requires careful planning of the light delivery and fiber insertion. We have developed an image-based approach, ... En savoir plus

This poster studies catalytic micropumps and their ability to induce fluid flow on the microscale. The goal of the study is to design a long-distance, directed convective loop. An array of catalytic micropumps was constructed in the domain, comprised of two distinct catalysts in an ... En savoir plus

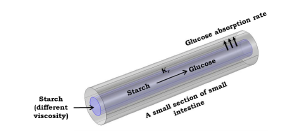

Digestion is the process of breaking down food into smaller components, by mechanical and enzymatic action in the digestive tract, so that the smaller nutrient molecules can be more easily absorbed in the intestinal tract. To study and analyze the human digestive process, different ... En savoir plus

Manufacturing of pharmaceutical drug substances involves chemical unit operations that are dependent on effective mixing, particularly reactions and crystallizations. Poor mixing can cause uneven distribution of chemical species in stirred tanks, leading to impurity formation and ... En savoir plus

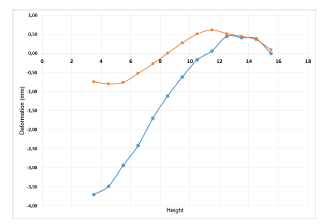

The liquid food product packaging are today predominantly made with board LPB type board (Liquid Packaging Board) composite formed by board, which offers mechanical strength, polyethylene, constituent responsible for protection against the passage humidity, and aluminum foil, which helps ... En savoir plus