- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

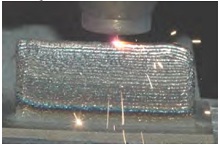

A Laser-welded blank (LWB) consists of steels of different thicknesses and/or grades welded together to produce a single blank prior to the forming process. LWB are mostly used in the automotive field where the high productivity of the laser welding process is an advantage. Numerical ... En savoir plus

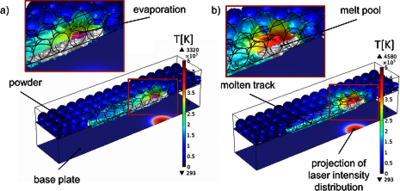

Laser additive manufacturing has become an interesting field of engineering which is revolutionizing industrial processes. Selective Laser melting (SLM) is a widely used additive manufacturing technique for 3D printing of metal structures. This process has a particular complexity in ... En savoir plus

Laser direct deposition is a process, different from molding or machining, which allows the producing of fully densified and operational components. This technique involves injecting metal powder through a coaxial nozzle into a melt pool obtained by a moving laser beam. The final object ... En savoir plus

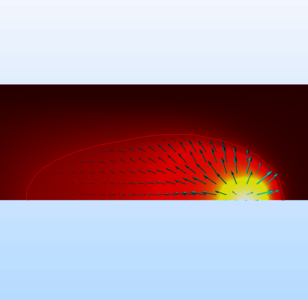

In a commercial 3D printer head, plastic ribbon passes through a hot nozzle of an extruder to dispense liquid plastic droplets to construct the model. In this paper a 2D axisymmetric model of a 3D head is considered to study the secondary transition change from below the glass ... En savoir plus

Selective Laser Melting (SLM) offers great potential for future manufacturing technology. In order to extend its applicability for the processing of high melting materials like molybdenum fundamental process understanding is required. This can be obtained by multiphysical simulations ... En savoir plus

Advances in protective and restorative biotherapies have created new opportunities to address vestibular disorders, deafness, and noise induced-, sensorineural-, and age-related hearing loss. Controllable and implantable drug delivery micropumps are essential for therapy development in ... En savoir plus

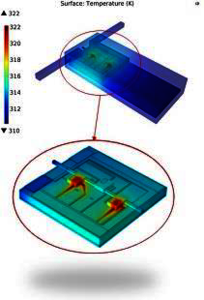

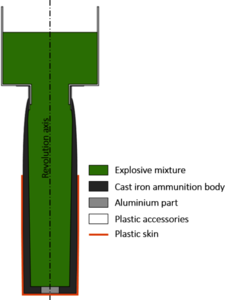

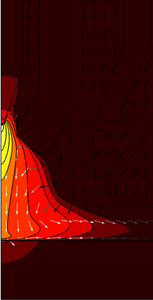

In the scope of improvement of the industrial “ammunition cooling” process, a COMSOL Multiphysics® model is developed to transfer an existing cooling process. A device filled with a liquid explosive mixture is placed in an apparatus which controls the environment temperature. This ... En savoir plus

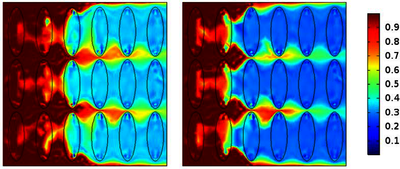

连续纤维增强金属基复合材料(Continuous Fiber Reinforcement Metal Matrix Composites)因其优异的性能而在汽车领域航空航天领域、兵器武装领域及电子及光学领域备受关注。但是,目前其制备工艺的不成熟,使得产品存在较多的空隙缺陷,对材料性能造成不良的影响,而压力浸渗制备的FRM相对致密、缺陷少而具有广阔的发展前景。本文以FRM的压力浸渗制备工艺为研究对象,利用Comsol Multiphysics软件进行二维数值模拟计算,分别研究了流体动力粘度、入口压力以及纤维排布方式等对渗流过程的影响,并判断出孔隙高频出现的区域 ... En savoir plus

One of the challenges associated with the wire-arc additive manufacture (WAAM) of metals is to provide adequate inert gas shielding, not only for the molten pool, but also for the long reactive metal surface that follows it. For Ti-6Al-4V, it has been shown that increased levels of ... En savoir plus

Latent heat storage devices use the melting enthalpy of a so-called phase change material (PCM) to store thermal energy. Open porous metals, such as 3D wire structures, allow the design of systems with tailored storage capacity and power. A geometric unit cell was identified, modelled ... En savoir plus