- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

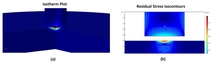

Arc current welding is a widespread process in heavy industry for the assembly of metallic components. In order to ensure the good quality of assemblies welds, it is appropriate to master the welding process but also to have a deep understanding of interactions with the weld pool and ... En savoir plus

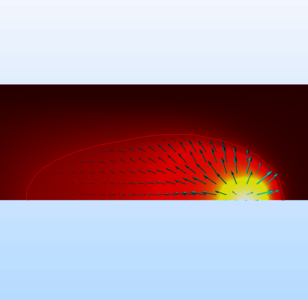

For a better understanding of phenomena associated to the appearance of defects in laser welding, a heat and fluid flow model is developed. This study is focused on the modeling of a static laser shot on a sample of steel. This 2D axialsymmetric configuration is used to study phenomena ... En savoir plus

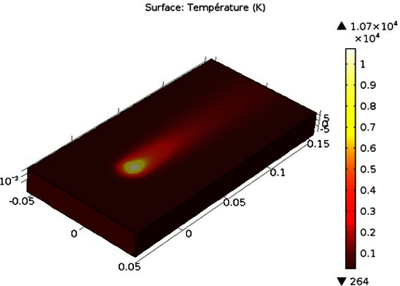

Laser additive manufacturing has become an interesting field of engineering which is revolutionizing industrial processes. Selective Laser melting (SLM) is a widely used additive manufacturing technique for 3D printing of metal structures. This process has a particular complexity in ... En savoir plus

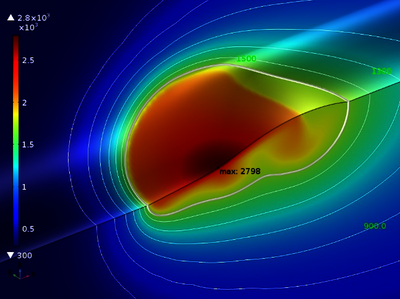

The interaction of high power laser beam with metallic materials produces a number of interconnected phenomena that represent a serious challenge for numerical modeling, especially for creation of auto-consistent models. Additional difficulty consists in lack of data on materials ... En savoir plus

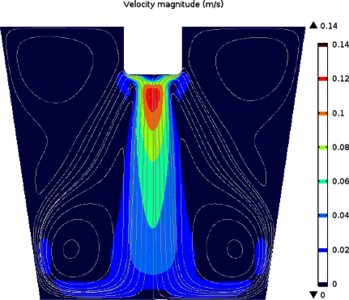

Acoustic streaming (AS) describes a physical phenomenon where an oscillating sound emitter induces a steady fluid motion. Metal processing industry applies this treatment for grain morphology adjustments during the solidification of metal. Improvement and further development of this ... En savoir plus

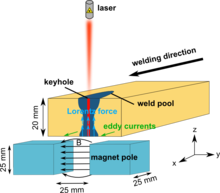

The application of an oscillating magnetic field on the high-power full-penetration laser beam welding process of a 20 mm thick stainless steel plate was numerically and experimentally investigated. In the simulations, three-dimensional heat transfer and fluid dynamics as well as ... En savoir plus

The initiation in numerical modeling of welding with COMSOL Multiphysics® is proposed to the 2nd year students of the professional master program «Processes, Controls, Metallic Materials: Nuclear Industry» (PC2M) of University of Burgundy, France since 2016 within the module «Simulation ... En savoir plus

Electrical Discharge Machining (EDM) is a non-conventional process used for machining electrically conducting materials. In die sink-EDM, sparks are generated between tool and workpiece resulting in heating of both electrode surfaces and creating a melt pool of metal which leads to ... En savoir plus

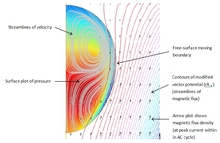

The aim of this article is to demonstrate the capability of the software for predicting free-surface motion and internal fluid flow in an electromagnetically levitated sample of liquid metal. Multiphysics solutions which demonstrate the usefulness of Comsol as a powerful MHD simulation ... En savoir plus

Improved performance of aeroengines requires the development of new manufacturing technologies for ceramic matrix composites (CMCs). This has been simulated using COMSOL Multiphysics. Specialized simulation technologies have been developed to describe the infiltration of molten material ... En savoir plus