- Bridging the Terahertz Gap

- Modeling the Lithium-Ion Battery

- Protection contre la Corrosion

- Modélisation des batteries

- Modélisation et Simulation dans le développement des piles à combustible

- Modélisation thermique des petits satellites

- Analyse électro-vibroacoustique d'un transducteur à armature équilibrée

Consultez les proceedings de la Conference COMSOL 2024

The Finite Element Method (FEM) has become an established numerical tool used for different academic and industrial purposes. It allows the prediction of weld pool geometry, thermal cycle, final distortion and residual stress field during and after fusion welding. The capability of the ... En savoir plus

In this paper describes an original method for indirect measurement of the vapor pressure and temperature in the keyhole in electron beam welding. This method is based on the determination of the concentration of chemical elements in the vapor above the welding zone. Taking into account ... En savoir plus

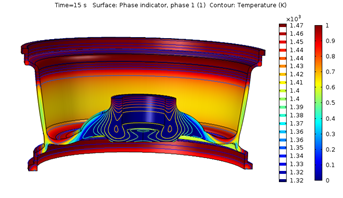

Casting product performance depends on material, flow, Process Temperature, Solidification, Shrinkage and residual stress. In a casting process, not all available resources are utilized effectively which results in low quality of casting, defects and metal wastage. Physics based modeling ... En savoir plus

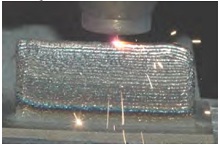

Laser direct deposition is a process, different from molding or machining, which allows the producing of fully densified and operational components. This technique involves injecting metal powder through a coaxial nozzle into a melt pool obtained by a moving laser beam. The final object ... En savoir plus

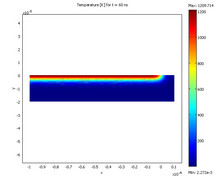

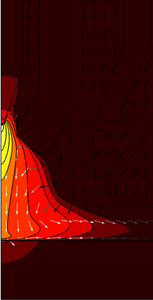

A 2D transient heat conduction model was created in COMSOL Multiphysics to simulate temperature changes in material irradiated by a KrF laser beam confined on silicon’s surface. In this paper, the obtained results are shown and discussed in case of bulk Silicon. The heat source is ... En savoir plus

Laser beam welding is a key technology in industrial manufacturing as it combines high flexibility and the potential for automation with excellent joint quality and minimal thermal influence of the workpiece. Whereas for materials like steel and aluminium laser beam welding is already ... En savoir plus

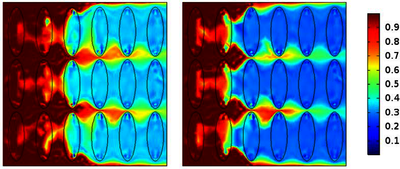

连续纤维增强金属基复合材料(Continuous Fiber Reinforcement Metal Matrix Composites)因其优异的性能而在汽车领域航空航天领域、兵器武装领域及电子及光学领域备受关注。但是,目前其制备工艺的不成熟,使得产品存在较多的空隙缺陷,对材料性能造成不良的影响,而压力浸渗制备的FRM相对致密、缺陷少而具有广阔的发展前景。本文以FRM的压力浸渗制备工艺为研究对象,利用Comsol Multiphysics软件进行二维数值模拟计算,分别研究了流体动力粘度、入口压力以及纤维排布方式等对渗流过程的影响,并判断出孔隙高频出现的区域 ... En savoir plus

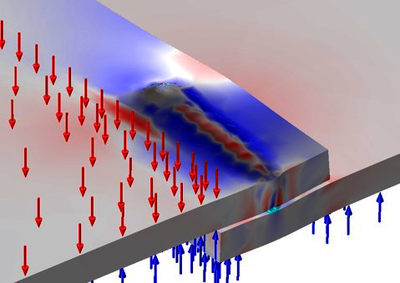

One of the challenges associated with the wire-arc additive manufacture (WAAM) of metals is to provide adequate inert gas shielding, not only for the molten pool, but also for the long reactive metal surface that follows it. For Ti-6Al-4V, it has been shown that increased levels of ... En savoir plus

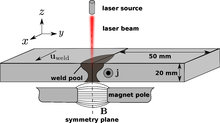

The article deals with the magnetically-supported high-power full-penetration laser beam welding of aluminum. A stationary simulation was conducted accounting for the effects of natural convection, Marangoni convection and solid-liquid phase transition as well as an electromagnetic ... En savoir plus

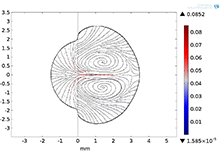

COMSOL Multiphysics® is used to simulate the transport phenomena in arc welding of Nickel to 304SS. Electric Currents (ec) and Magnetic Fields (mf) are used to solve for the Lorentz force which is one of the volume forces. Laminar Flow (spf) is used to simulate flow field. The Lorentz ... En savoir plus