Evènements

Méthodologie de modélisation

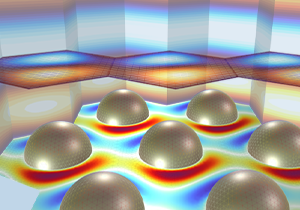

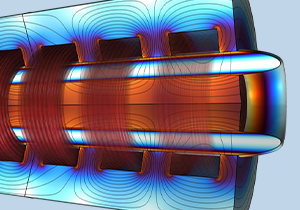

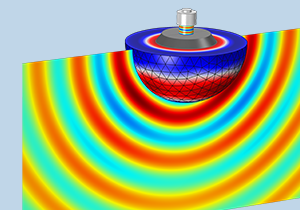

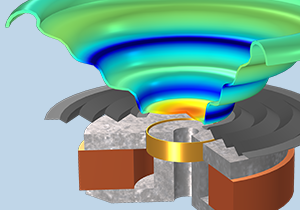

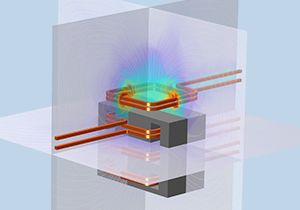

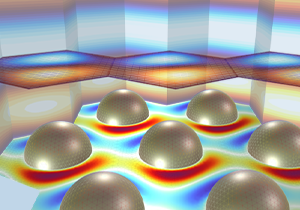

Electromagnétisme

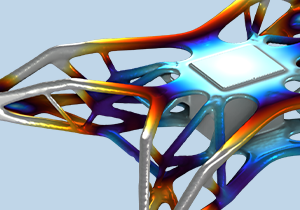

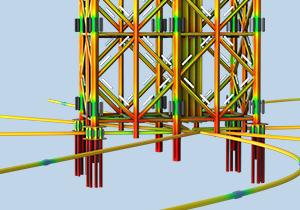

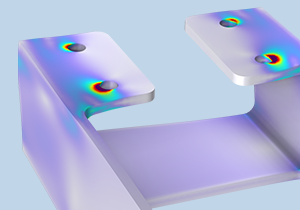

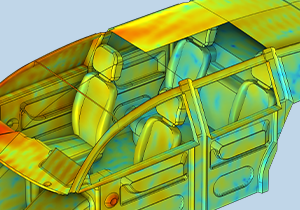

Structure & acoustique

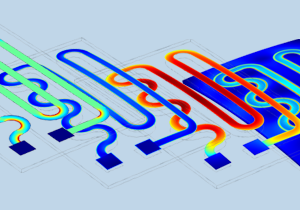

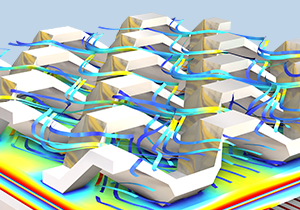

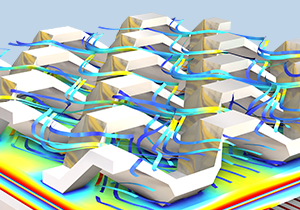

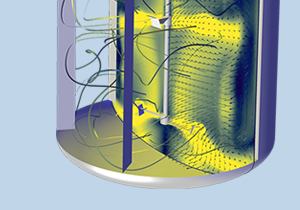

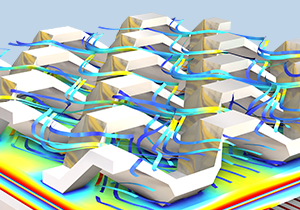

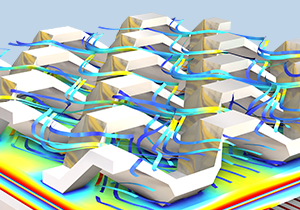

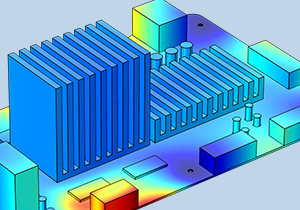

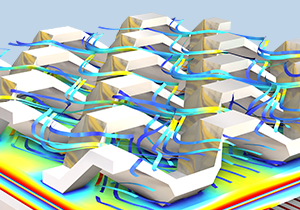

Fluide & thermique

Chimie

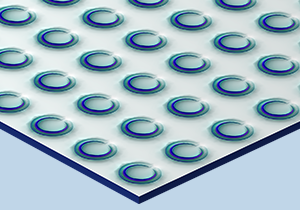

Interfaces

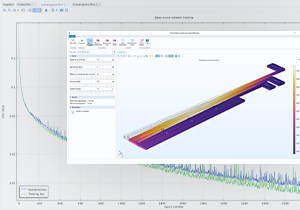

Général

Affichage:

Fuseau horaire:

Mon fuseau horaire (EST)

Horaire organisateur

08:00 AM - 08:00 PM

Evènements démarrant entre: 08:00 – 20:00

Recherche

Evènements à venir

Chargement des Évènements

janv. 6–9

| 12:00 PST

CES

COMSOL

Exhibition

Las Vegas

janv. 13–16

| 11:00 EST

Introduction to COMSOL Multiphysics®

COMSOL

Formation

En ligne

janv. 13

| 14:00 EST

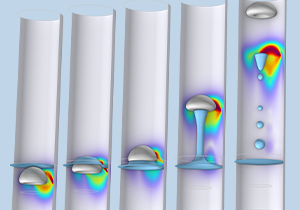

Polymer Flow Modeling

COMSOL

Webinaire

En ligne

janv. 15

| 11:00 EST

COMSOL Day: Version 6.4

COMSOL

COMSOL Day

En ligne

janv. 20

| 08:00 CET

The Basics of COMSOL® in 18 Minutes

COMSOL

Webinaire

En ligne

janv. 20–23

| 11:00 EST

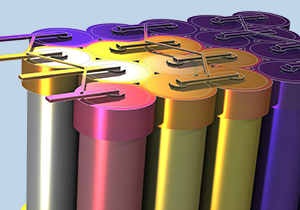

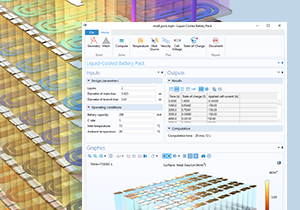

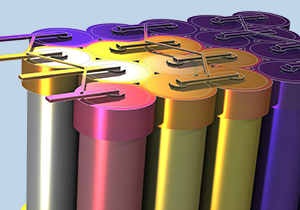

Battery Modeling in COMSOL Multiphysics®

COMSOL

Formation

En ligne

janv. 22

| 14:00 EST

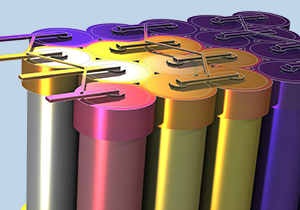

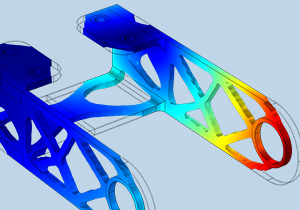

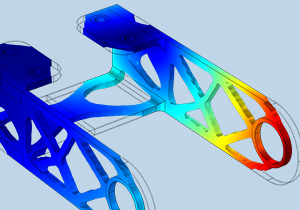

Shape and Topology Optimization with COMSOL Multiphysics®

COMSOL

Webinaire

En ligne

janv. 27–30

| 11:00 EST

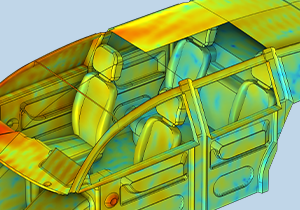

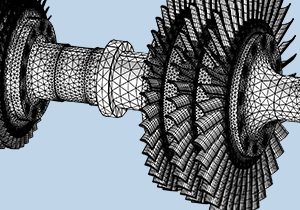

Structural Mechanics Modeling in COMSOL Multiphysics®

COMSOL

Formation

En ligne

janv. 27

| 11:30 EST

The Basics of COMSOL Multiphysics® in 18 Minutes

COMSOL

Webinaire

En ligne

janv. 29

| 09:00 GMT

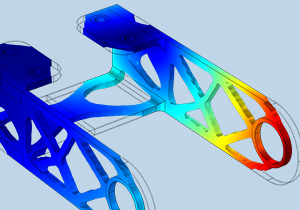

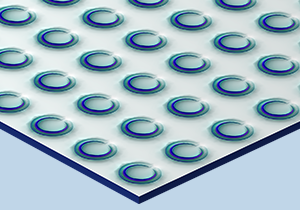

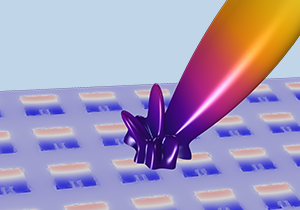

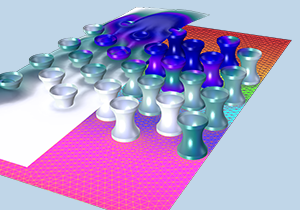

Modeling Photonic Crystals in COMSOL Multiphysics

COMSOL

Webinaire

En ligne

janv. 29

| 14:00 EST

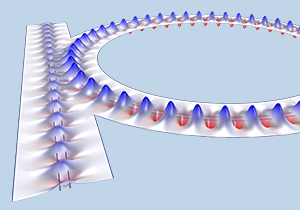

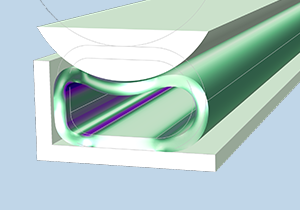

Simulating Optical Waveguides

Laser Focus World

Webinaire

En ligne

févr. 3

| 08:00 CET

Topology Optimization with COMSOL® in 18 Minutes

COMSOL

Webinaire

En ligne

févr. 10–13

| 11:00 EST

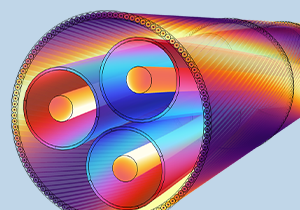

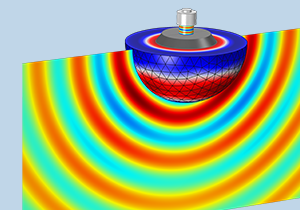

RF Modeling in COMSOL Multiphysics®

COMSOL

Formation

En ligne

févr. 17

| 08:00 CET

Heat Transfer Modeling with COMSOL® in 18 Minutes

COMSOL

Webinaire

En ligne

févr. 24

| 14:00 EST

Uncertainty Quantification for Acoustics

COMSOL

Webinaire

En ligne

févr. 26

| 09:00 GMT

The Basics of COMSOL® in 18 Minutes

COMSOL

Webinaire

En ligne

févr. 26

| 14:00 EST

Modeling Rotordynamics with COMSOL Multiphysics®

COMSOL

Webinaire

En ligne

mars 3

| 08:00 CET

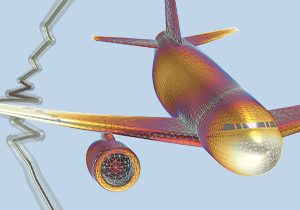

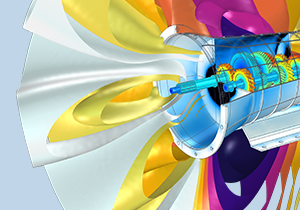

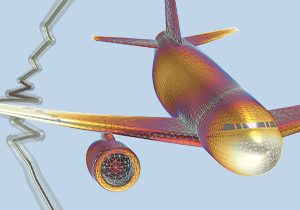

Modeling for Aerospace Engineering with COMSOL Multiphysics®

COMSOL

Webinaire

En ligne

mars 3–6

| 11:00 EST

Introduction to COMSOL Multiphysics®

COMSOL

Formation

En ligne

mars 3

| 14:00 EST

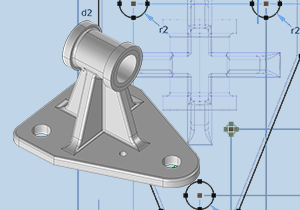

Editing, Repairing, and Combining Imported STL Files with CAD

COMSOL

Webinaire

En ligne

mars 10–13

| 11:00 EDT

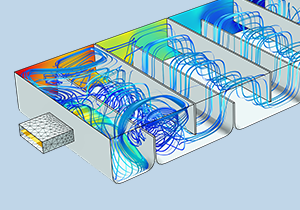

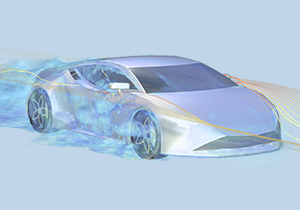

CFD Modeling in COMSOL Multiphysics®

COMSOL

Formation

En ligne

mars 17

| 09:00 CET

CFD Modeling with COMSOL Multiphysics® in 18 Minutes

COMSOL

Webinaire

En ligne

mars 24–27

| 11:00 EDT

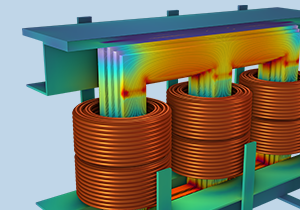

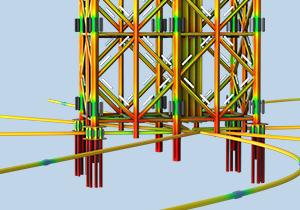

AC/DC Modeling in COMSOL Multiphysics®

COMSOL

Formation

En ligne

avr. 14–17

| 11:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Formation

En ligne

avr. 21–24

| 11:00 EDT

Heat Transfer Modeling in COMSOL Multiphysics®

COMSOL

Formation

En ligne

avr. 28–29

| 09:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Formation

Burlington

mai 5–8

| 11:00 EDT

Acoustics Modeling in COMSOL Multiphysics®

COMSOL

Formation

En ligne

mai 19–22

| 11:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Formation

En ligne

juin 23–26

| 11:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Formation

En ligne

Affichage de 8 sur 29 évènements

Affichage de 29 sur 29 évènements

| Date | Time | Title | Type | Host | Discipline |

|---|---|---|---|---|---|

| janv. 6–9 | 12:00 |

CES |

Evènement spécial | COMSOL-Las Vegas |

|

| janv. 13–16 | 11:00 |

Introduction to COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| janv. 13 | 14:00 |

Polymer Flow Modeling |

Webinaire | COMSOL-En ligne |

|

| janv. 15 | 11:00 |

COMSOL Day: Version 6.4 |

COMSOL Day | COMSOL-En ligne |

|

| janv. 20 | 08:00 |

The Basics of COMSOL® in 18 Minutes |

Webinaire | COMSOL-En ligne |

|

| janv. 20–23 | 11:00 |

Battery Modeling in COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| janv. 22 | 14:00 |

Shape and Topology Optimization with COMSOL Multiphysics® |

Webinaire | COMSOL-En ligne |

|

| janv. 27–30 | 11:00 |

Structural Mechanics Modeling in COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| janv. 27 | 11:30 |

The Basics of COMSOL Multiphysics® in 18 Minutes |

Webinaire | COMSOL-En ligne |

|

| janv. 29 | 09:00 |

Modeling Photonic Crystals in COMSOL Multiphysics |

Webinaire | COMSOL-En ligne |

|

| janv. 29 | 14:00 |

Simulating Optical Waveguides |

Webinaire | Laser Focus World - En ligne |

|

| févr. 3 | 08:00 |

Topology Optimization with COMSOL® in 18 Minutes |

Webinaire | COMSOL-En ligne |

|

| févr. 10–13 | 11:00 |

RF Modeling in COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| févr. 17 | 08:00 |

Heat Transfer Modeling with COMSOL® in 18 Minutes |

Webinaire | COMSOL-En ligne |

|

| févr. 24 | 14:00 |

Uncertainty Quantification for Acoustics |

Webinaire | COMSOL-En ligne |

|

| févr. 26 | 09:00 |

The Basics of COMSOL® in 18 Minutes |

Webinaire | COMSOL-En ligne |

|

| févr. 26 | 14:00 |

Modeling Rotordynamics with COMSOL Multiphysics® |

Webinaire | COMSOL-En ligne |

|

| mars 3 | 08:00 |

Modeling for Aerospace Engineering with COMSOL Multiphysics® |

Webinaire | COMSOL-En ligne |

|

| mars 3–6 | 11:00 |

Introduction to COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| mars 3 | 14:00 |

Editing, Repairing, and Combining Imported STL Files with CAD |

Webinaire | COMSOL-En ligne |

|

| mars 10–13 | 11:00 |

CFD Modeling in COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| mars 17 | 09:00 |

CFD Modeling with COMSOL Multiphysics® in 18 Minutes |

Webinaire | COMSOL-En ligne |

|

| mars 24–27 | 11:00 |

AC/DC Modeling in COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| avr. 14–17 | 11:00 |

Introduction to COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| avr. 21–24 | 11:00 |

Heat Transfer Modeling in COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| avr. 28–29 | 09:00 |

Introduction to COMSOL Multiphysics® |

Formation | COMSOL-Burlington |

|

| mai 5–8 | 11:00 |

Acoustics Modeling in COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| mai 19–22 | 11:00 |

Introduction to COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

| juin 23–26 | 11:00 |

Introduction to COMSOL Multiphysics® |

Formation | COMSOL-En ligne |

|

Webinaires à la demande

Solving Large Models in COMSOL Multiphysics®

Webinaire

Jan 06

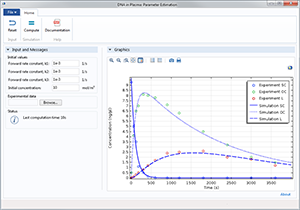

Parameter Estimation for Nonlinear Materials

Webinaire

Dec 11

Modéliser le contact mécanique avec COMSOL Multiphysics®

Webinaire

Dec 11

Introducing COMSOL Multiphysics® Version 6.4

Webinaire

Dec 10

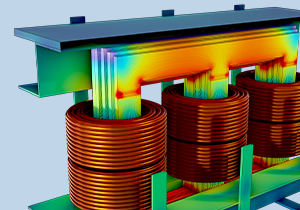

Multiphysics Simulation of Power Transformers

Webinaire

Dec 09

Modéliser les dispositifs médicaux et biomédicaux avec COMSOL Multiphysics®

Webinaire

Dec 04

Multiphysics Simulation for Vehicle Electrification

Webinaire

Dec 02

Optimising Manufacturing Processes Through Simulation

Webinaire

Nov 26

Designing Efficient Electric Motors with COMSOL Multiphysics

Webinaire

Nov 26

Efficient Battery Modeling with Surrogate Models

Webinaire

Nov 19

Automating Your Modeling Workflow in COMSOL Multiphysics®

Webinaire

Nov 18

Modéliser le packaging et les tests de dispositifs électroniques avec COMSOL Multiphysics®

Webinaire

Nov 13

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinaire

Nov 11

Modeling Pipe Flow & Heat in COMSOL Multiphysics®

Webinaire

Nov 06

Modeling Gyroscopes and Accelerometers in COMSOL Multiphysics®

Webinaire

Oct 30

Modéliser les écoulements turbulents avec COMSOL Multiphysics®

Webinaire

Oct 16

Modeling and Simulation for Electric Motor Design

Webinaire

Oct 15

Simulating Electrical Power Systems for the Grid

Webinaire

Oct 14

Unravelling Chemomechanical Effects in Lithium-Ion Batteries

Webinaire

Oct 09

Modeling Next-Generation Battery Technologies with COMSOL Multiphysics®

Webinaire

Oct 06

Modeling Emerging Battery Technologies with COMSOL Multiphysics®

Webinaire

Sep 25

Modéliser le rayonnement thermique avec COMSOL Multiphysics®

Webinaire

Sep 25

Modeling and Simulation of MEMS Devices

Webinaire

Sep 23

Modéliser les moteurs électriques et les générateurs avec COMSOL Multiphysics®

Webinaire

Sep 18

Modeling Reaction Kinetics and Pharmacokinetics with COMSOL Multiphysics®

Webinaire

Sep 11

Modeling Ultrasound for Biomedical Applications

Webinaire

Sep 09

Optimization of Thermal Management Systems

Webinaire

Sep 03

Prediction of Electromagnetic Signatures of Naval Vessels with COMSOL Multiphysics

Webinaire

Aug 28

Bonnes pratiques pour évaluer et afficher les résultats dans COMSOL Multiphysics®

Webinaire

Aug 28

Modeling Room Acoustics in COMSOL Multiphysics®

Webinaire

Aug 19

Modeling and Simulation for Electric Motor Design

Webinaire

Aug 14

Moisture Transport Modeling in COMSOL Multiphysics®

Webinaire

Aug 07

Modeling Hydrogen Fuel Cells and Electrolyzers

Webinaire

Aug 06

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinaire

Aug 05

Modeling Acoustic Metamaterials in COMSOL Multiphysics

Webinaire

Jul 31

Multiphysics Modeling of Power Electronics

Webinaire

Jul 29

Fatigue and Durability Analysis Using COMSOL Multiphysics®

Webinaire

Jul 24

Comment créer des modèles de substitution avec COMSOL Multiphysics®

Webinaire

Jul 24

Biomedical Modeling with COMSOL Multiphysics

Webinaire

Jul 17

Understanding Liquid Metal Transport in Magnetic Fields — Simulating Magnetohydrodynamic Duct Flow

Webinaire

Jul 11

Modeling Electric Motors and Drivetrains

Webinaire

Jul 10

Créer des applications de simulation et des jumeaux numériques avec COMSOL Multiphysics®

Webinaire

Jul 10

Memristor Modeling with COMSOL Multiphysics®

Webinaire

Jul 02

Modeling Fluid Mixers and Stirred Tank Reactors in COMSOL Multiphysics®

Webinaire

Jun 26

Underwater Acoustics

Webinaire

Jun 12

Hydrogen Technology Innovation with Simulation

Webinaire

Jun 12

Optimization in Structural Mechanics

Webinaire

Jun 12

Modeling Hydrogen Fuel Cells and Electrolyzers

Webinaire

Jun 12

Améliorer la gestion thermique des dispositifs électroniques avec COMSOL Multiphysics®

Webinaire

Jun 12

Modeling Chemical Reactions and Reacting Flows Using COMSOL Multiphysics®

Webinaire

Jun 05

Introduction to Multibody Dynamics Modeling with COMSOL Multiphysics

Webinaire

May 28

Automotive Acoustics Analysis Using COMSOL Multiphysics®

Webinaire

May 27

Comment faire de l’optimisation et de l’estimation de paramètres avec COMSOL Multiphysics®

Webinaire

May 22

Acoustics in Electronics Series, Part 4: Piezoelectric Devices

Webinaire

May 20

Modélisation multiphysique pour l’aéronautique et le spatial avec COMSOL Multiphysics®

Webinaire

May 13

Improving Thermal Management of Batteries with COMSOL Multiphysics®

Webinaire

May 09

Acoustics in Electronics Series, Part 3: Hearing Aids

Webinaire

May 06

Comment utiliser le solveur temporel de COMSOL Multiphysics®

Webinaire

Apr 24

Modéliser les Batteries avec COMSOL Multiphysics®

Webinaire

Apr 17

Acoustics in Electronics Webinar Series, Part 2: MEMS Speakers and Microphones

Webinaire

Apr 16

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinaire

Apr 15

Wave & Ray Optics Modeling with COMSOL®

Webinaire

Apr 09

Optimization in RF and Wave Optics

Webinaire

Apr 09

Meshing Your Models in COMSOL Multiphysics®

Webinaire

Apr 08

Multiphysics Simulation in Semiconductor Packaging

Webinaire

Apr 03

Acoustics in Electronics Webinar Series, Part 1: Loudspeakers

Webinaire

Mar 25

Simulating Electrical Power Systems for the Grid

Webinaire

Mar 20

Comment Utiliser Efficacement les Études Stationnaires de COMSOL Multiphysics®

Webinaire

Mar 20

Multiphysics Modeling of Electronic Components

Webinaire

Mar 20

Using Geometry Modeling Tools in COMSOL Multiphysics®

Webinaire

Mar 18

Improving Thermal Management of Batteries with COMSOL Multiphysics®

Webinaire

Mar 18

Modéliser les Composants Électroniques avec COMSOL Multiphysics®

Webinaire

Mar 13

Modeling Chemical Reactions and Reacting Flows Using COMSOL Multiphysics®

Webinaire

Mar 06

Integrating Frequency-Dependent Data into Time-Domain Acoustics Analysis

Webinaire

Feb 27

Introduction to Uncertainty Quantification

Webinaire

Feb 26

Efficient Battery Modeling with Surrogate Models

Webinaire

Feb 18

Comment construire un maillage dans COMSOL Multiphysics®

Webinaire

Feb 18

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinaire

Feb 13

Modéliser la Corrosion et les Systèmes de Protection contre la Corrosion avec COMSOL Multiphysics®

Webinaire

Feb 13

Designing a Magnetorheological-Fluid-Based Clutch Using COMSOL Multiphysics®

Webinaire

Feb 13

Modeling Biochemical Sensors and Testing Devices with COMSOL®

Webinaire

Jan 29

Modeling Optical Nanostructures with COMSOL Multiphysics®

Webinaire

Jan 23

Améliorer les Performances des Piles à Combustible et des Électrolyseurs avec COMSOL Multiphysics®

Webinaire

Jan 23

Electric Discharge Modeling

Webinaire

Jan 21

Automotive Acoustics Analysis Using COMSOL Multiphysics®

Webinaire

Jan 16

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinaire

Jan 14

Comment Construire efficacement sa Géométrie avec le Module Design

Webinaire

Jan 14

Affichage de 6 sur 87 évènements

Affichage de 87 sur 87 évènements

- Informations Produit

- Produits

- Grille des Spécifications

- Types de Licence

- Configuration Requise

- Historique des Versions

- Société

- A propos de COMSOL

- Carrières

- Presse

- Contact

- |

- Politique de confidentialité

- |

- Trademarks

- |

- Cookie Settings

- © 2026 by COMSOL. Tous Droits réservés