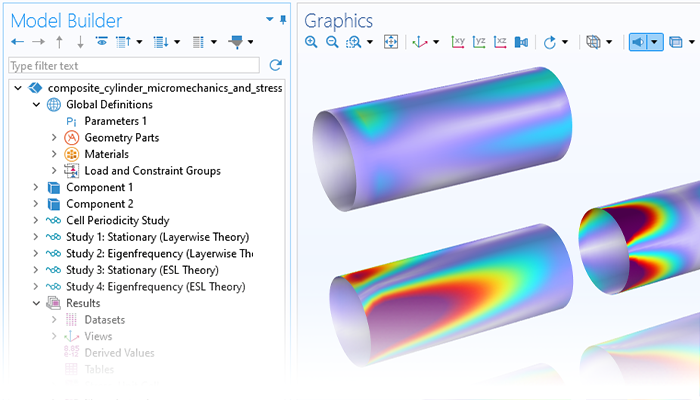

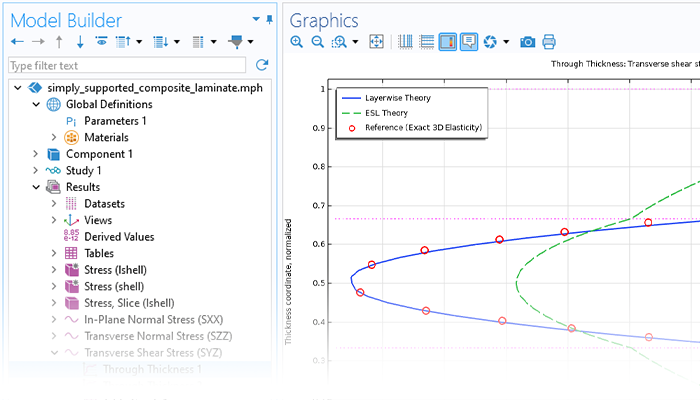

Le module Composite Materials utilise la technologie spécialisée des matériaux multicouches et fournit deux approches qui peuvent être utilisées pour modéliser les coques composites avec précision: la théorie par couches et la théorie de couche équivalente. L'approche par couche est adaptée aux coques composites épaisses à modérément fines avec un nombre limité de couches. La théorie ESL convient aux coques minces à modérément épaisses et peut contenir de nombreuses couches sans impact significatif sur les performances. Il est également possible de combiner ces deux théories pour analyser les composites stratifiés. Ces théories peuvent être utilisées pour optimiser l'empilement d'un stratifié et d'autres paramètres en effectuant des analyses multi-échelles, multi-physiques, et diverses analyses de ruptures.

Module Composite Materials

Modéliser les structures composites pour améliorer la conception des produits

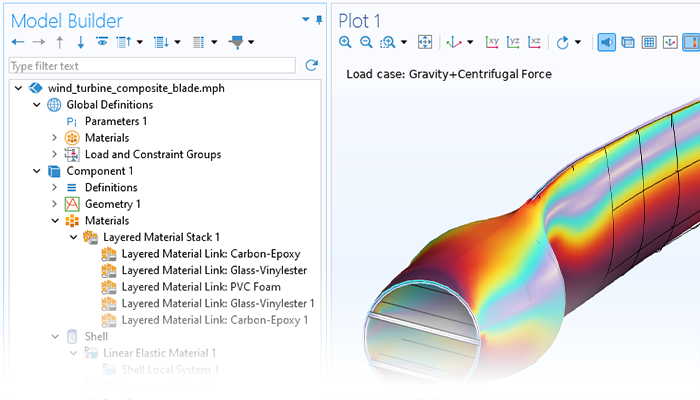

Un matériau composite est un matériau hétérogène composé de deux ou plusieurs constituants intégrés pour améliorer les performances structurelles. Le module Composite Materials est une extension du module Structural Mechanics qui inclut des outils de modélisation spécialisés et des fonctionnalités pour l'analyse des structures composites stratifiées. Les matériaux composites stratifiés, tels que les polymères renforcés par des fibres, les plaques laminées et les panneaux sandwichs, sont largement utilisés dans la fabrication de composants aéronautiques, d'engins spatiaux, de pales d'éoliennes, de composants automobiles, de bâtiments, de coques de bateaux, de bicyclettes et d'équipements de sécurité.

En complément, le module Composite Materials peut être combiné avec d'autres modules de la suite de produits COMSOL, ce qui permet de prendre en compte, par exemple, le transfert de chaleur, l'électromagnétisme, l'écoulement de fluides, l'acoustique et les effets piézoélectriques dans les modèles de matériaux composites.

Contacter COMSOL

Théorie des stratifiés pour définir et visualiser les stratifiés

L'analyse des coques composites stratifiées est généralement basée sur la théorie par couches ou la théorie de couche équivalente (ESL).

Ce que permet de modéliser le module Composite Materials

Effectuer diverses analyses structurelles pour les stratifiés composites avec le logiciel COMSOL®.

Micromécanique et macromécanique

Calculer les propriétés homogénéisées des matériaux et les réponses macroscopiques des composites stratifiés.

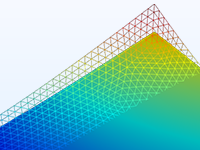

Analyse multiéchelle

Évaluer la réponse structurelle d'une structure composite à l'échelle macroscopique ainsi qu'à l'échelle microscopique.

Matériaux non linéaires1

Incorporer des modèles de matériaux non linéaires dans un composite stratifié.

Délamination

Modéliser l'initiation et la propagation de la délamination dans un composite stratifié.

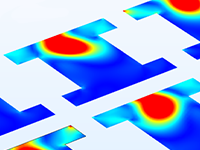

Flambage linéaire

Calculer les facteurs de charge critiques et déformées modales de flambage sous chargement de compression.

Rupture de la première couche

Évaluer l'intégrité structurelle d'une coque composite stratifiée.

Optimisation des composites2

Optimiser l'empilement des composites, l'épaisseur des couches, l'orientation des fibres et les propriétés des matériaux.

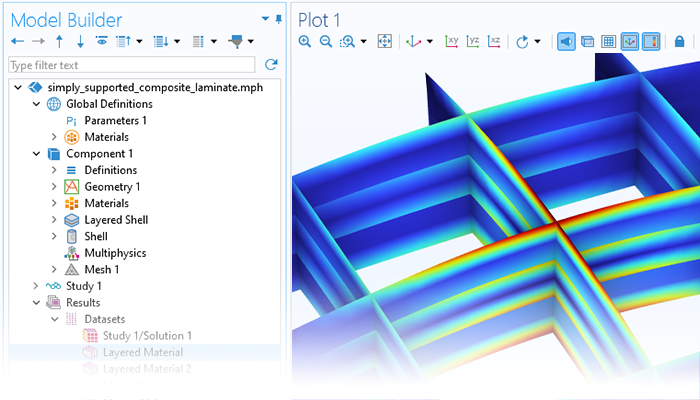

Connexions structurelles

Coupler les éléments coques et coques multicouches avec d'autres éléments structurels à l'aide de couplages multiphysiques.

- Nécessite le module Nonlinear Structural Materials.

- Nécessite le module Optimization

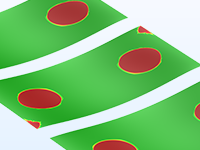

Outils spécialisés pour définir et visualiser les stratifiés

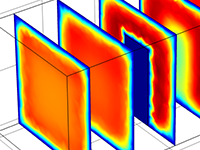

Le module Composite Materials offre un ensemble d'outils spécialisés permettant de visualiser les stratifiés composites constitués de plusieurs couches.

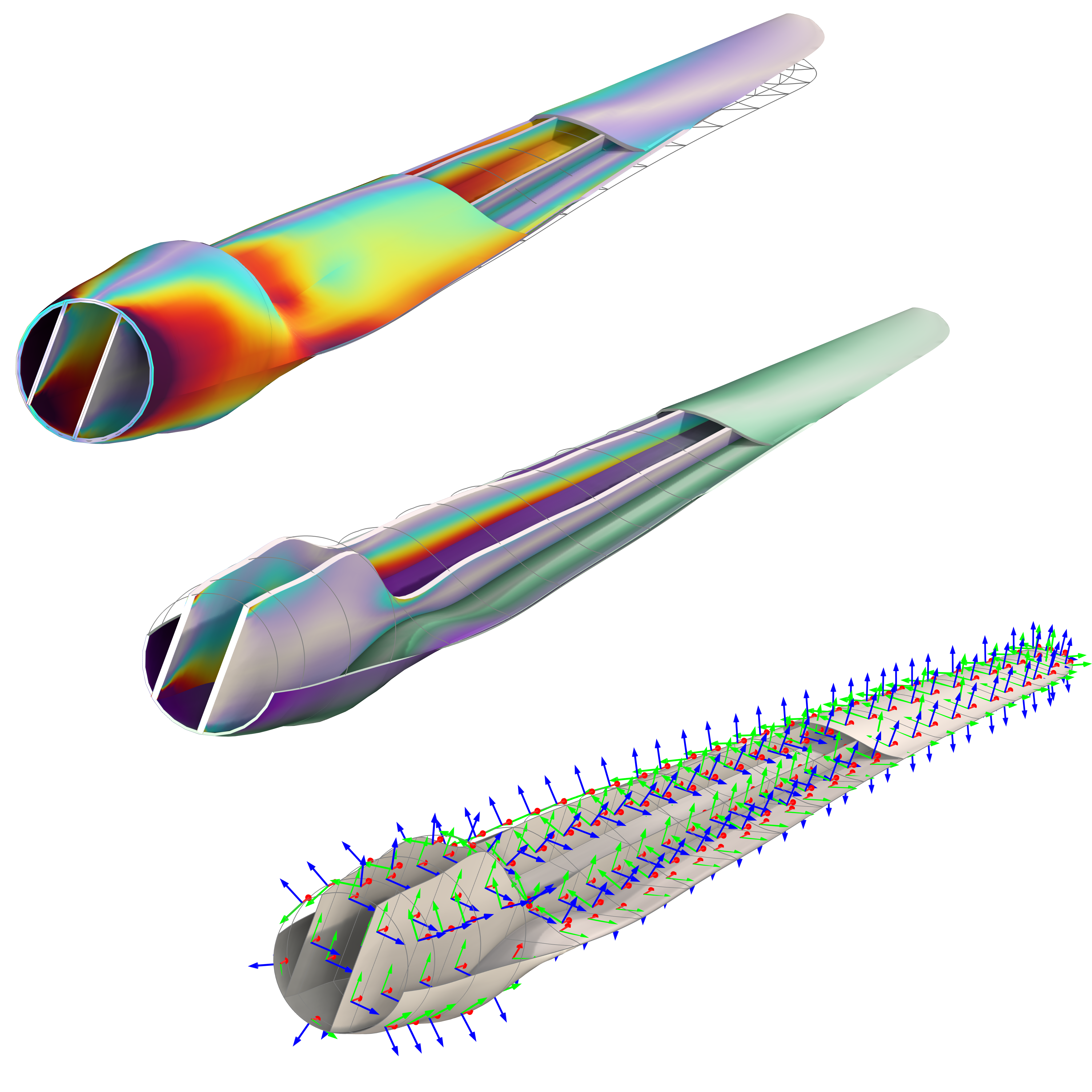

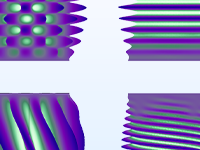

Interface Coque multicouche

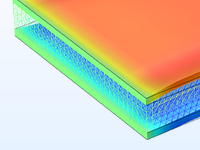

L'interface Coque multicouche, disponible en 3D, fournit une approche basée sur la théorie Layerwise pour une analyse détaillée des stratifiés composites. Les matériaux des différentes couches peuvent être non linéaires. Elle inclut également des fonctions de forme de différents ordres pour le champ de déplacement dans la surface de référence et dans la direction de l'épaisseur. L'interface Coque multicouche inclut des distributions complètes de contraintes et de déformations en 3D, ce qui permet par exemple de calculer les contraintes interlaminaires et d'étudier les variations de contraintes à l'intérieur de chaque couche.

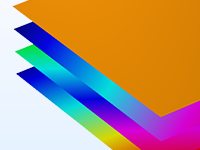

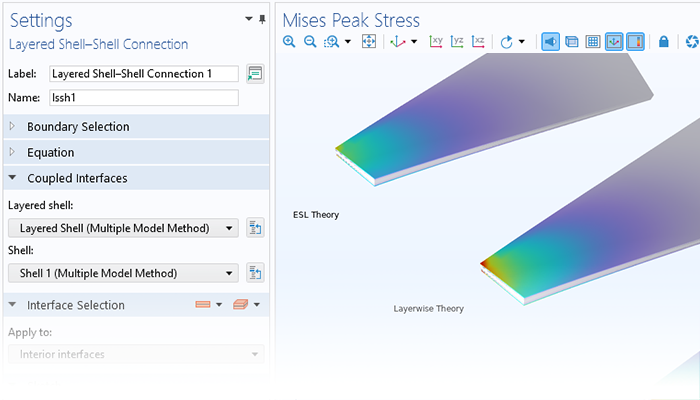

Approche multi-modèles

L'interface Coque multicouche basée sur la théorie par couches est précise mais coûteuse en ressources de calcul. L'interface Coque basée sur une théorie de couche équivalente est moins coûteuse en ressources de calcul, mais ne permet pas d'obtenir des résultats précis dans l'épaisseur de la couche. L'approche multi-modèles — qui combine les deux théories dans différentes parties d'un composite stratifié — est le meilleur choix en termes de précision et de performance pour la modélisation de structures composites en sandwich.

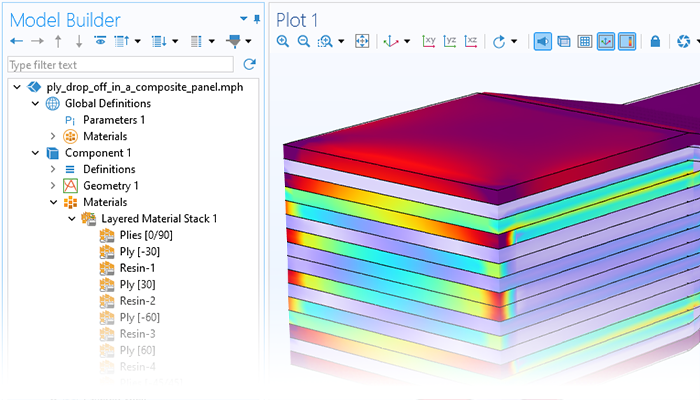

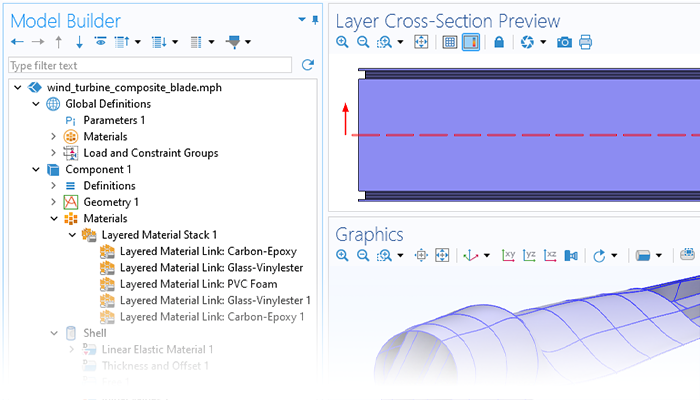

Fonctionnalité Matériau multicouche

Le noeud Matériau multicouche peut être utilisé pour définir un empilement où chaque couche possède ses propres données matériau, son épaisseur, et son orientation principale. Il existe des fonctionnalités pour définir des propriétés matériaux pour les interfaces entre les couches. Les matériaux multicouches définis de cette manière peuvent être combinés à l'aide du noeud Lien avec les matériaux multicouches ou Empilement de matériaux multicouches pour créer des matériaux multicouches plus complexes, ceci étant particulièrement pratique pour les empilements répétitifs, symétriques, ou antisymétriques. Ces noeuds incluent des boutons permettant de visualiser des aperçus 2D ou 3D de composites laminés.

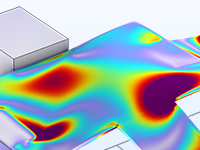

Graphique en coupe du matériau multicouche

Le graphique Coupe du matériau multicouche offre plus de liberté en termes de création de coupe dans un stratifié composite. Cette fonctionnalité est utile dans les cas suivants : lors de la création d'une coupe uniquement à travers une ou plusieurs couches sélectionnées, lors de la création d'une coupe à travers certaines des couches, mais sans nécessairement les placer dans la direction de l'épaisseur, ou bien lors de l'examen détaillé d'une couche spécifique et la création d'une coupe à un endroit particulier de la couche qui soit différent du plan médian.

Interface Coque

L'interface Coque est complétée par une loi de comportement matériau, basée sur la théorie des couches équivalentes, qui calcule les propriétés matérielles homogénéisées de l'ensemble du stratifié et ne résout que le plan médian. Divers effets non-élastiques tels que la plasticité et la viscoplasticité peuvent être ajoutés aux différentes couches du stratifié. Les résultats incluent des distributions complètes de contraintes et de déformations en 3D, ce qui permet par exemple d'étudier les variations des contraintes à l'intérieur de chaque couche.

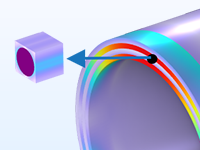

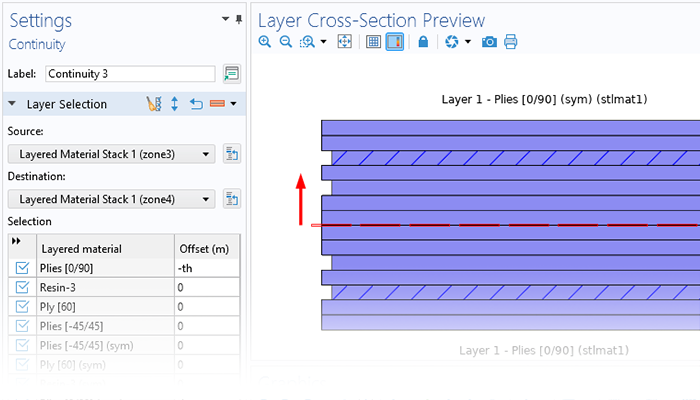

Connexion de matériaux multicouches

Lors de l'assemblage de deux stratifiés différents dans une configuration côte à côte ou de la modélisation d'une situation de lâcher de plis, il est possible d'utiliser le noeud Empilement de matériaux multicouches avec le noeud Continuité dans l'interface Coque multicouche. La zone de connexion des deux stratifiés peut être contrôlée par différentes options. Les couches connectées des deux stratifiés peuvent être visualisées à l'aide du graphique Aperçu de la section de la couche disponible dans le noeud Continuité.

Jeu de données sur les matériaux multicouches

Le jeu de données Matériau multicouche est utilisé pour afficher les résultats de la simulation sur une géométrie qui a une épaisseur finie. Ce jeu de données peut être utilisé pour visualiser les stratifiés fins. Le jeu de données fournit la possibilité d'évaluer les résultats aux noeuds du maillage, aux interfaces, ou aux plans médians, et il est également possible de sélectionner ou de déselectionner certaines couches du stratifié.

Graphique dans l'épaisseur

Le graphique Dans l'épaisseur permet de visualiser la variation de n'importe quelle quantité à un endroit précis de la frontière en fonction de l'épaisseur du stratifié. Un ou plusieurs points géométriques de la frontière peuvent être sélectionnés, des jeux de données de points peuvent éventuellement être crées. Il est également possible de spécifier directement les coordonnées des points. Contrairement aux autres graphiques, la quantité résultat est représentée sur l'axe x, tandis que la coordonnée de l'épaisseur est représentée sur l'axe y.

Approfondir les analyses grâce aux couplages multiphysiques

Il existe deux types d'interactions fondamentalement différentes entre la mécanique dans les stratifiés et d'autres phénomènes physiques pouvant avoir lieu au sein du stratifié. Pour les processus physiques qui se produisent à l'intérieur du stratifié, il est possible de résoudre l'ensemble des phénomènes physiques simultanément, y compris les couplage entre ceux-ci. Dans d'autres configurations, le stratifié est modélisé comme une frontière d'un domaine 3D où plusieurs phénomènes physiques ont lieu. Les couplages multiphysiques suivants sont disponibles avec les couplages intégrés:

- Transfert de chaleur1

- Courants électriques2

- Piézoélectricité2

- Poroélasticité3

- Interaction acoustique-composite4

- Interaction fluide-composite5

- Nécessite le module Heat Transfer

- Nécessite le module AC/DC ou le module MEMS

- Nécessite le module Porous media

- Nécessite le Module Acoustics

- Pour un écoulement turbulent, nécessite le module CFD

Transfert de chaleur et courants électriques

Modéliser le chauffage par effet Joule et la dilatation thermique dans un composite stratifié avec une technologie de matériaux multicouches.

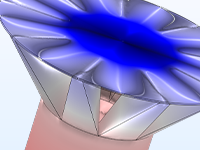

Piézoélectricité

Simuler les composites piézoélectriques utilisés pour créer des structures intelligentes telles que des capteurs ou des actionneurs.

Interaction acoustique–composite

Modéliser la vibroacoustique dans un composite stratifié en couplant le stratifié avec un domaine acoustique environnant.

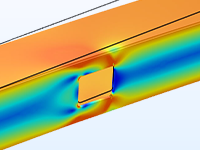

Interaction fluide-composite

Utiliser les interfaces Coque et Coque multicouche pour modéliser des composites stratifiés en interaction avec des domaines fluides.

Chaque activité et chaque besoin en matière de simulation est unique.

Afin d'évaluer pleinement si le logiciel COMSOL Multiphysics® répond ou non à vos exigences, nous vous invitons à nous contacter. En parlant à l'un de nos représentants, vous obtiendrez des recommandations personnalisées et des ressources détaillées qui vous aideront à tirer le meilleur parti de votre évaluation et vous guideront pour choisir l'option la plus adaptée à vos besoins en matière de licence.

Il vous suffit de cliquer sur le bouton "Contacter COMSOL", d'indiquer vos coordonnées et tout commentaire ou toute question spécifique et de soumettre votre demande. Vous recevrez une réponse d'un représentant de COMSOL très rapidement.

Prochaine étape:

Demander une démonstration du logiciel