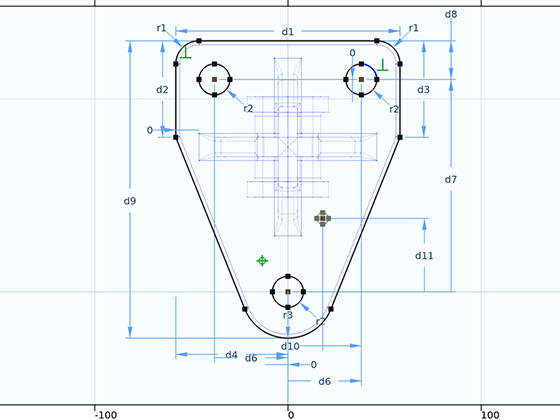

Contraintes et dimensions

Le module Design comprend un ensemble d'outils d'esquisses utilisés pour ajouter des contraintes et des dimensions aux dessins planaires pour les modèles 2D, les plans de travail 3D et les pièces géométriques. Parmis les options de contraintes disponibles, le module Design propose l'ajout de contraintes parallèles, perpendiculaires et tangentes. Par exemple, pour que deux segments de polygone se rejoignent à 90 degrés, il suffit de cliquer sur les deux arêtes et d'utiliser une contrainte de perpendicularité. Les options pour les dimensions comprennent, entre autres, la spécification de contraintes de longueur, de rayon et d'angle. Pour définir interactivement une contrainte de longueur, par exemple, il suffit de cliquer sur une arête et de la faire glisser. Pour aider à créer des dessins cohérents, le module Design donne un retour immédiat, indiquant si une esquisse est sous-définie, surdéfinie ou correctement conçue.

Toutes les dimensions détaillées ci-dessus peuvent être rendues paramétriques à l'aide des fonctionnalités paramétriques générales de COMSOL Multiphysics®. Cela permet d'exécuter des balayages paramétriques sur une, ou plusieurs, dimensions. De plus, en combinaison avec le module Optimization, des optimisations paramétriques peuvent être réalisées.