Modélisation précise d'écoulements de gaz à basse pression et basse vitesse

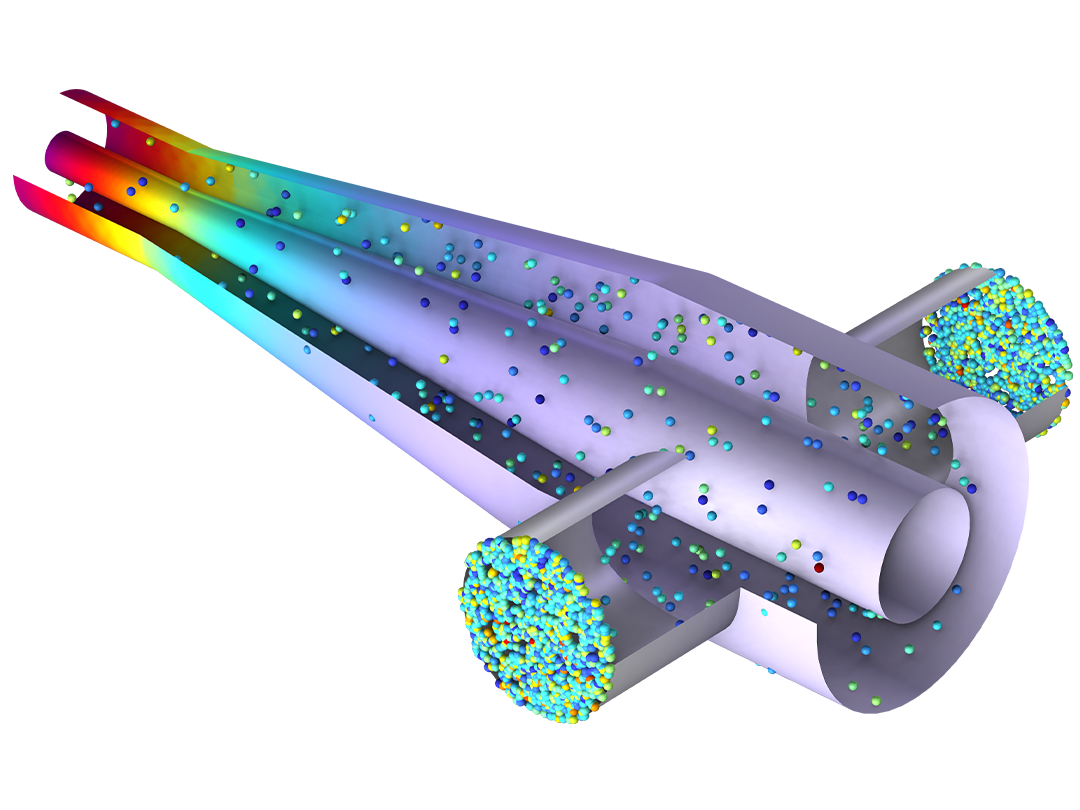

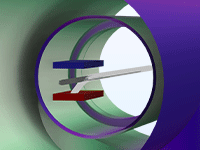

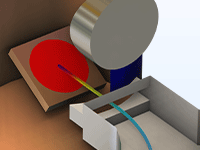

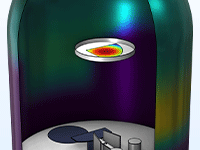

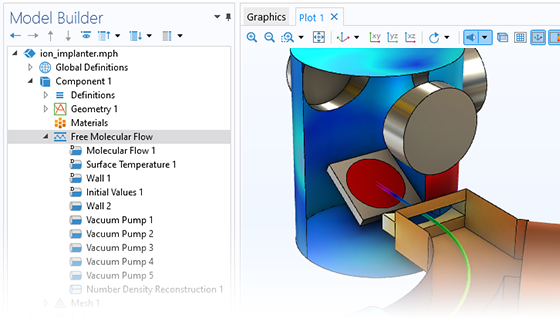

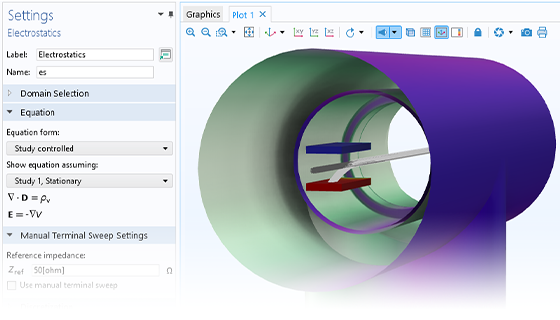

Le module Molecular Flow est idéal pour simuler des systèmes sous vide, incluant ceux utilisés dans les procédés de fabrication des semiconducteurs, les accélérateurs de particules, et les spectromètres de masse. Les applications impliquant des petits canaux, comme l'exploitation du gaz de schiste ou des écoulements dans des matériaux nanoporeux, peuvent également être adressées.

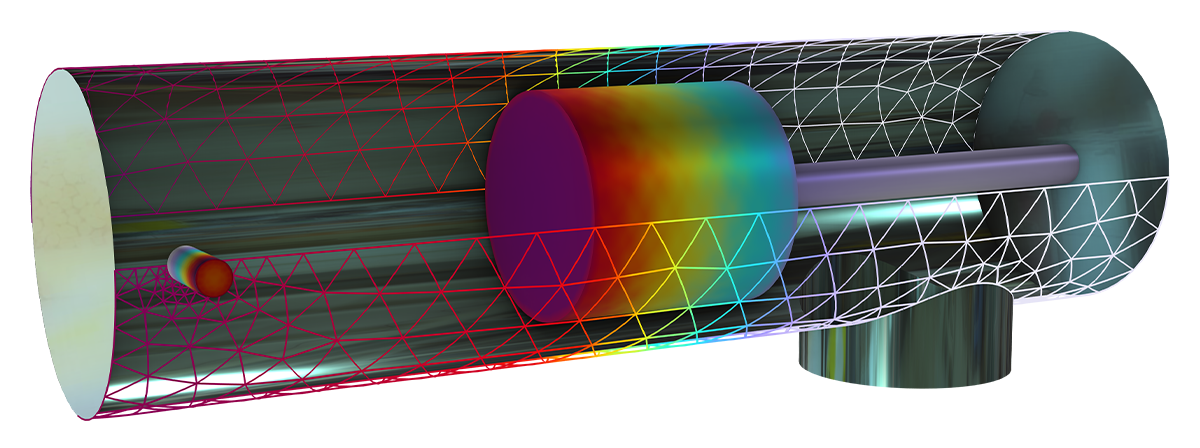

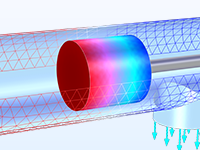

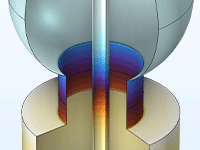

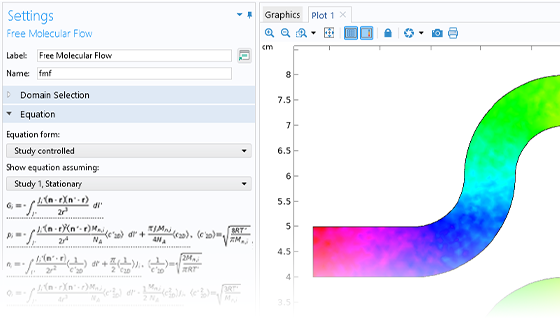

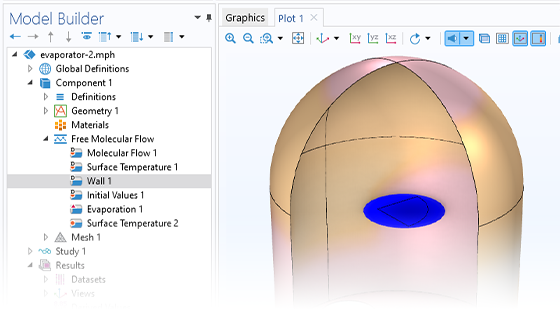

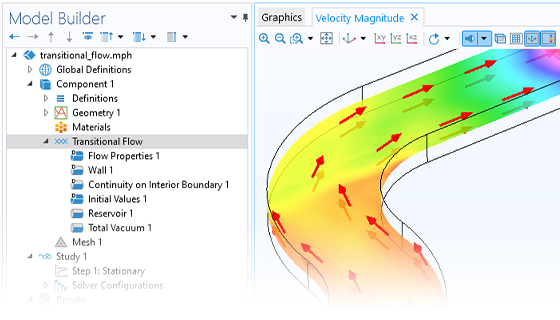

La méthode du coefficient angulaire est utilisée dans le module pour simuler des écoulements moléculaires libres en régime stationnaire, permettant de calculer les flux moléculaires, la pression et les flux de chaleur au niveau des surfaces. La densité de population peut être reconstruite au sein des domaines, surfaces, arêtes ou points à partir des flux moléculaires des surfaces alentour. Il est également possible de modéliser des écoulements moléculaires isothermes et non isothermes et de calculer les contributions des molécules de gaz aux flux de chaleur.