Plasmas à couplage inductif

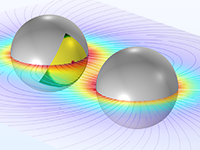

Etudier comment la puissance se transfère au plasma dans un réacteur ICP.1

Modéliser les plasmas à basse température et les plasmas thermiques

Un plasma fait intervenir de multiples phénomènes physiques en interaction qui affectent son comportement, comme par exemple la mécanique des fluides, les réactions chimiques avec notamment les réactions de surface, la cinétique physique, le transfert de chaleur et de masse, et l'électromagnétisme. Le module Plasma est un produit complémentaire spécialisé de COMSOL Multiphysics® pour la modélisation des décharges à hors équilibre et à l'équilibre, qui se produisent dans un large panel de disciplines d'ingénierie. Développé pour traiter des systèmes très variés, le module Plasma fournit des paramètres prédéfinis pour la modélisation des décharges à courant continu (DC), des plasmas à couplage inductif (ICP), des plasmas micro-ondes, des plasmas à couplage capacitif (CCP) et des décharges corona. Contacter COMSOL

Simuler le comportement des plasmas soumis à diverses excitations électromagnétiques.

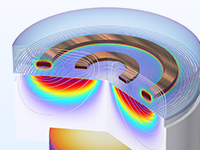

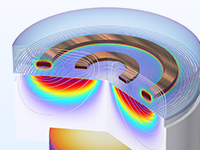

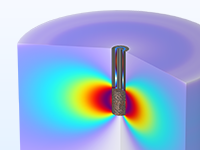

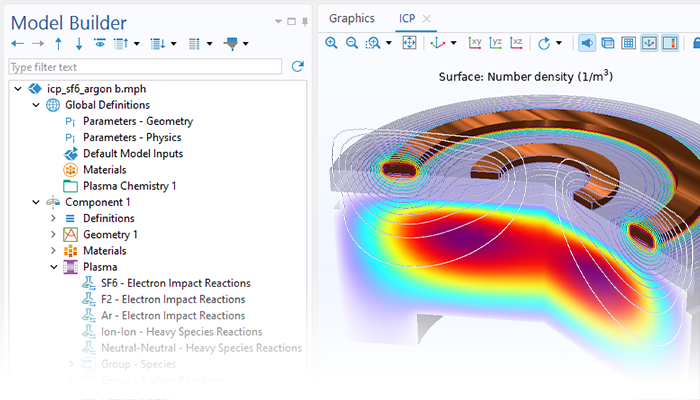

Etudier comment la puissance se transfère au plasma dans un réacteur ICP.1

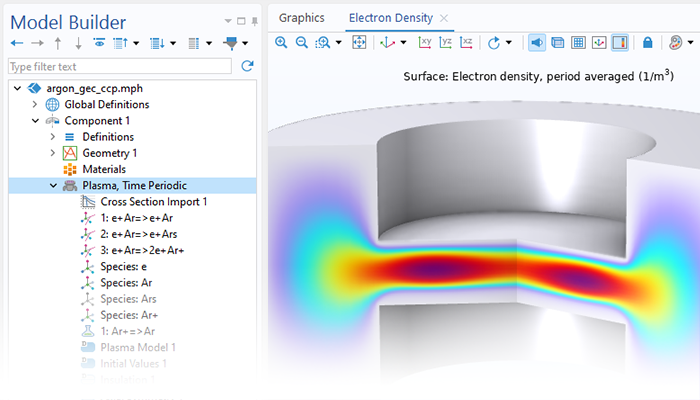

Modéliser les réacteurs CCP à l'aide d'une interface dédiée qui résout directement le régime permanent en condition périodique.

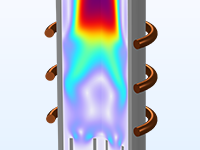

Étudier comment un biais RF à couplage inductif influence un réacteur ICP.1

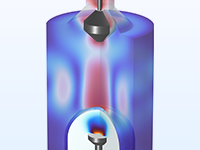

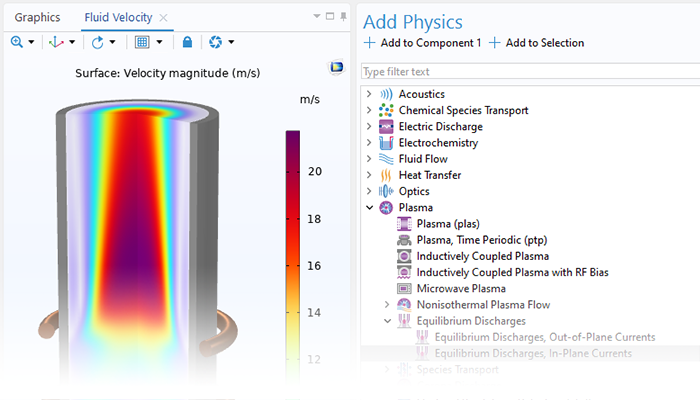

Coupler un modèle de plasma avec l'écoulement fluide et le transfert de chaleur.

Coupler un modèle de plasma avec des champs magnétiques et des ondes électromagnétiques pour modéliser une source de plasma ECR.1,2

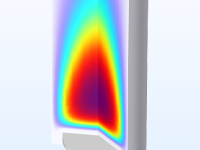

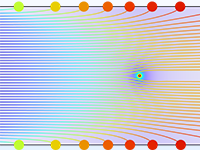

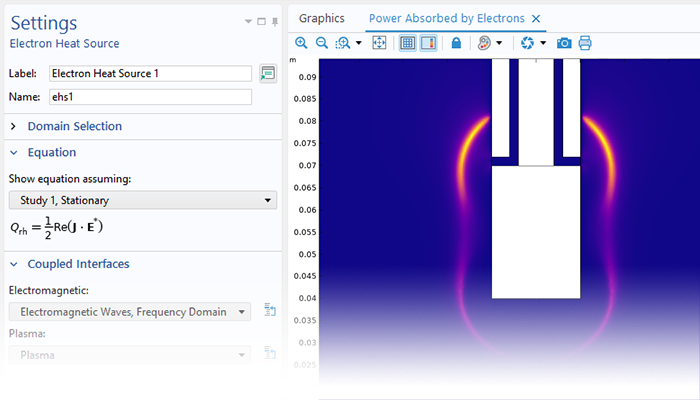

Etudier les effets du chauffage par micro-ondes dans un plasma.2

Simuler des décharges entretenues par une tension ou un courant continu.

Calculer la distribution spatiale des espèces chargées dans les décharges corona.

Déterminer si le gaz d'un système à haute tension DC peut subir une décharge.

Suivre les trajectoires des particules chargées et calculer la probabilité de transmission dans un précipitateur électrostatique.3

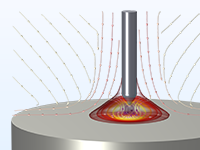

Simuler la distribution de température dans un plasma d'arcs et dans les matériaux en contact.1

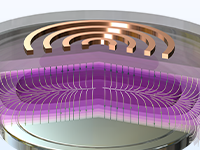

Etudier les caractéristiques électriques et thermiques d'une torche ICP à pression atmosphérique.1

Modéliser les réacteurs plasma à l'aide de modèles globaux pour des paramétrages rapides et des chimies complexes, incluant l'équation de Boltzmann.

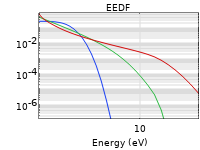

Calculer les EEDF et obtenir les paramètres de transport des électrons et les termes sources pour les utiliser dans les modèles fluides de plasmas.

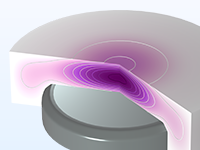

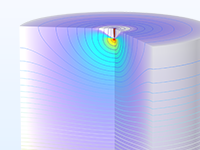

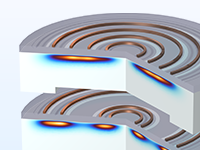

Optimiser la conception et le positionnement de la bobine d'un réacteur ICP pour obtenir l'uniformité du plasma.4

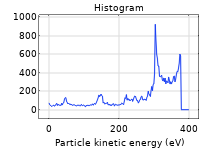

Calculer la fonction de distribution de l'énergie des ions sur les surfaces.3

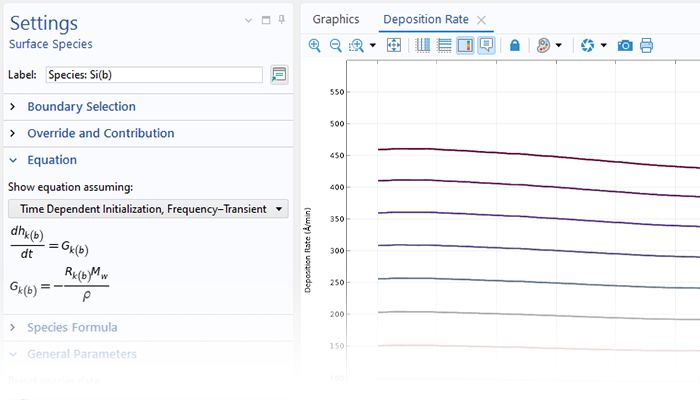

Simuler les vitesses de gravure et de croissance sur une surface.

Le module Plasma fournit des outils spécialisés pour la modélisation des plasmas à basse température et des plasmas thermiques.

Le module Plasma fournit des interfaces prédéfinies pour la modélisation des réacteurs plasma à basse température qui sont entretenus par un champ électrique, qu'il soit statique ou variable dans le temps. Ces interfaces définissent des ensembles d'équations sur les domaines, des conditions aux limites, des conditions initiales, des maillages prédéfinis, des études prédéfinies avec des paramètres de solveur pour des analyses statiques et transitoires, ainsi que des graphiques prédéfinis et des valeurs dérivées. Les équations de transport pour toutes les espèces (électrons, ions et neutres) sont résolues de manière autoconsistante avec l'équation de Poisson. L'équation de l'énergie moyenne des électrons peut également être résolue en modélisant la façon dont les électrons gagnent de l'énergie à partir du champ électrique et en perdent lors des collisions avec le gaz ambiant.

La chimie des plasmas est extrêmement importante pour obtenir des résultats de simulation réalistes. Le module Plasma définit les réactions d'impact électronique, les réactions entre espèces lourdes et les réactions de surface.

La chimie du plasma détermine comment les électrons perdent ou gagnent de l'énergie lors des collisions avec le gaz ambiant. Le module Plasma offre des caractéristiques dédiées à la modélisation des réactions d'impact des électrons qui peuvent entraîner ionisation, excitation ou attachement. Les réactions d'impact des électrons peuvent être définies à partir des données de section efficaces de collisions, et les termes sources peuvent être obtenus par intégration appropriée sur les fonctions de distribution d'énergie électronique.

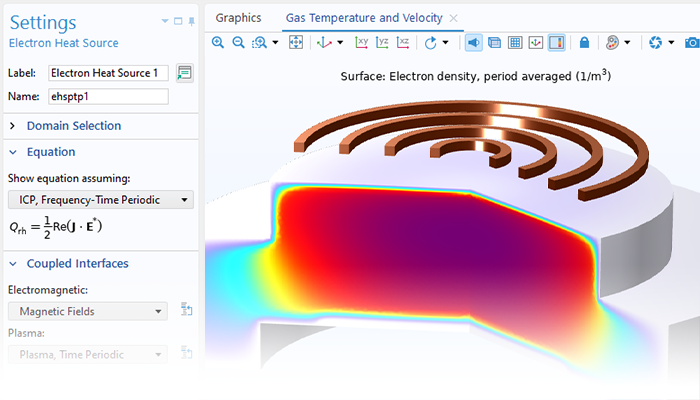

L'interface multiphysique Plasma avec couplage inductif1 est utilisée pour étudier les décharges qui sont entretenues par des courants inductifs. Cette interface multiphysique relie la conductivité du plasma de l'interface Plasma à l'interface Champs magnétiques et couple le chauffage des électrons résultant des courants induits à l'interface Plasma. Le champ magnétique est résolu dans le domaine fréquentiel et le plasma est résolu dans le domaine temporel.

Le module Plasma comprend des interfaces pour la modélisation des plasmas à l'équilibre thermodynamique. A l'équilibre thermodynamique, les électrons et les espèces lourdes ont la même température et le plasma peut être caractérisé par une température unique. Pour modéliser les plasmas dans de telles conditions, le module Plasma propose plusieurs interfaces Décharge à l'équilibre basées sur le type d'excitation électrique : Décharge DC à l'équilibre, Plasma inductif à l'équilibre1 et Décharge combinée inductive/DC1. Ces interfaces décrivent le plasma comme un fluide unique avec une température unique dans une approche magnétohydrodynamique. Les interfaces Décharge à l'équilibre couplent les interfaces d'écoulement de fluide, de transfert de chaleur, de champs magnétiques et de courants électriques. La physique du plasma est introduite par des caractéristiques de couplage multiphysique qui incorporent des sources de chaleur spécifiques dans le fluide et via les propriétés du plasma, comme la conductivité électrique, la capacité thermique, le transfert de chaleur par rayonnement, etc.

L'interface multiphysique Plasma micro-ondes2 est utilisée pour étudier les décharges qui sont entretenues par des ondes électromagnétiques (décharge alimentée par des ondes). Lorsque cette interface est sélectionnée, une interface Plasma et une interface Ondes électromagnétiques sont automatiquement générées, ainsi que leurs couplages multiphysiques. La caractéristique Couplage de la conductivité du plasma couple la conductivité du plasma à l'interface Ondes électromagnétiques, et la caractéristique Source de chaleur des électrons couple le chauffage des électrons qui en résulte à l'interface Plasma. Les ondes électromagnétiques sont résolues dans le domaine fréquentiel et le plasma est résolu dans le domaine temporel.

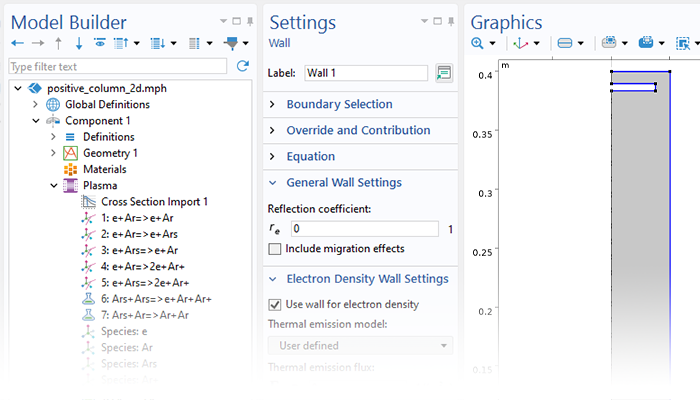

Parmi les interfaces intégrées au module Plasma, il existe diverses conditions aux limites permettant de décrire l'interaction entre un plasma et une surface. Par exemple, la densité électronique et les flux d'énergie à une surface sont facilement définis en appliquant la fonctionnalité Paroi, qui introduit les pertes par transport dans les équations de transport des électrons. Des sources de flux supplémentaires peuvent être ajoutées, comme l'émission d'électrons secondaires et les flux d'électrons génériques au niveau d'une surface.

Les flux de particules chargées sont automatiquement calculés aux électrodes et peuvent être ajoutés pour modéliser des circuits externes. Si un diélectrique est en contact avec le plasma, l'accumulation de charge de surface est calculée à partir des flux des espèces chargées à la surface.

Le module Plasma propose un ensemble de fonctionnalités permettant de modéliser les processus de gravure et de dépôt dans les procédés de fabrication des semi-conducteurs. Il résout les équations de transport du plasma en les couplant entièrement avec la cinétique des réactions de surface, ce qui permet l'échange dynamique d'espèces entre la surface et la phase gazeuse. Les modèles d'occupation des sites de surface peuvent être utilisés pour capturer avec précision les mécanismes de réaction auto-limitants. De plus, les vitesses de réaction en surface peuvent être spécifiées à l'aide de modèles de rendement de réaction dépendant de l'énergie, ce qui facilite la simulation détaillée de mécanismes tels que la gravure ionique réactive et les modifications de surface sélectives en énergie.

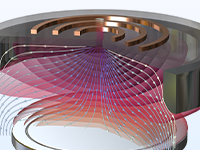

L'interface Plasma inductif avec polarisation RF1 est utilisée pour étudier les décharges entretenues par des courants d'induction et une polarisation RF. Cette interface multiphysique ajoute une interface Plasma, périodique en temps et une interface Champs magnétiques, et couple le chauffage des électrons résultant des courants d'induction à l'interface Plasma, périodique en temps. Le champ magnétique est résolu dans le domaine fréquentiel et le plasma est résolu dans le domaine temporel.

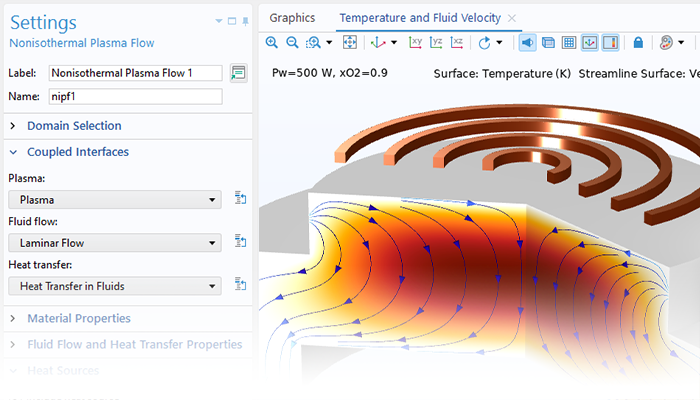

Les interfaces Ecoulement plasma non-isotherme combinent le plasma, les écoulements fluides et le transfert de chaleur pour modéliser l'écoulement et la thermique du gaz ambiant dans un réacteur à plasma. Le transfert de chaleur dans les matériaux entourant un plasma peut également être simulé. Le couplage multiphysique Ecoulement plasma non-isotherme calcule automatiquement les enthalpies résultant des réactions du plasma, pour les introduire dans l'interface de transfert de chaleur en tant que source de chaleur volumique. Les propriétés du fluide et les propriétés thermodynamiques telles que la viscosité et la conductivité thermique sont calculées par l'interface Plasma et transmises automatiquement aux interfaces d'écoulement et de transfert de chaleur.

Le module Plasma comprend une méthode numérique spécialisée pour la modélisation des CCP avec des temps de calcul nettement réduits par rapport aux méthodes traditionnelles. Au lieu de résoudre dans le domaine temporel, la solution périodique en régime permanent est calculée en ajoutant une dimension supplémentaire aux équations mathématiques sous-jacentes. Cette équation extra-dimensionnelle représente un cycle RF et lui impose des conditions limites périodiques. Cela évite de résoudre des dizaines, voire des centaines de milliers de cycles RF, avant que le plasma n'atteigne sa solution d'équilibre périodique. Cette approche conserve intégralement la non-linéarité du modèle tout en réduisant considérablement le temps de calcul.

Chaque activité et chaque besoin en matière de simulation est unique.

Afin d'évaluer pleinement si le logiciel COMSOL Multiphysics® répond ou non à vos exigences, nous vous invitons à nous contacter. En parlant à l'un de nos représentants, vous obtiendrez des recommandations personnalisées et des ressources détaillées qui vous aideront à tirer le meilleur parti de votre évaluation et vous guideront pour choisir l'option la plus adaptée à vos besoins en matière de licence.

Il vous suffit de cliquer sur le bouton "Contacter COMSOL", d'indiquer vos coordonnées et tout commentaire ou toute question spécifique et de soumettre votre demande. Vous recevrez une réponse d'un représentant de COMSOL très rapidement.

Demander une démonstration du logiciel